GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

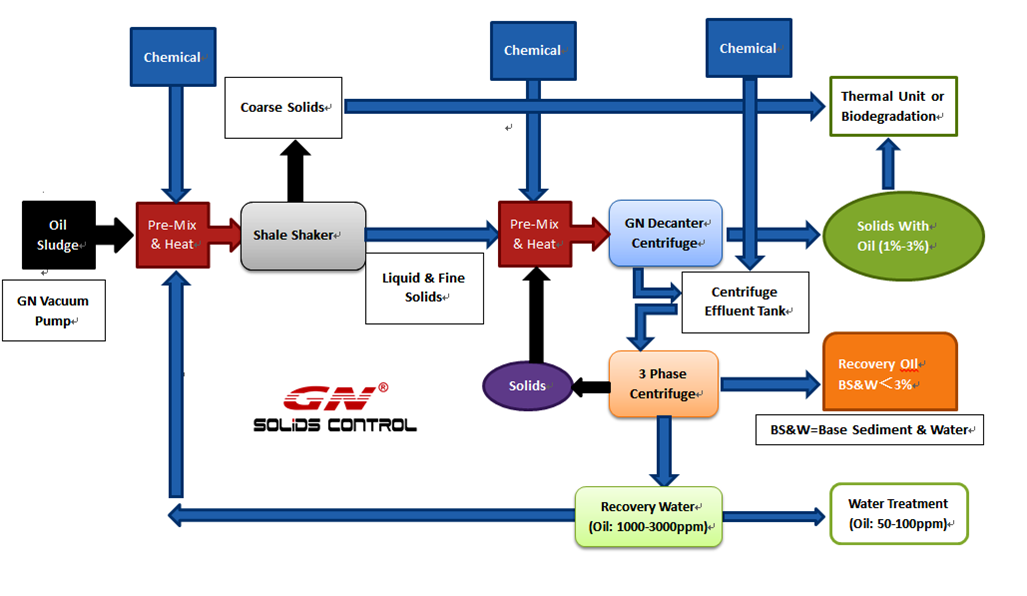

GN oily sludge treatment system can realize the complete treatment of the oily sludge hot washing process for users. The system can be used for the whole process of oily sludge material extraction, heating and conditioning, coarse particle screening, sludge dewatering, and oil-water-solid three-phase separation. GN oily sludge treatment system is a chemical-assisted mechanical separation process. Through the chemical hot washing process, the oil is eluted from the sludge, the sludge is dehydrated, and then the oil and water are separated. GN oily sludge treatment system is often used for oily sludge in oil refineries, drilling oily sludge, oil tank cleaning sludge, and industrial oily sludge treatment. As a manufacturer of integrated oily sludge system, GN can provide customized solutions based on the analysis of customers' oily sludge.

| Model | GNOST-01 | GNOST-05 | GNOST-15 |

|---|---|---|---|

| Conditioning Capacity | 1-2 m3/h | 5 m3/h | 15 m3/h |

| The above specification and parameters for reference only. | |||

| Item | Process | Description |

|---|---|---|

| 1 | Sludge Picking Up | The oily sludge is extracted from the oily sludge pit by the GN solid vacuum pump or excavator. |

| 2 | Heating & Conditioning | Stirring, pre-mixing and conditioning is performed in heating the pre-mixing tank. |

| 3 | Screening Treatment | After heated and conditioned, the oily sludge will be treated by vibrating screen for coarse particles separation. |

| 4 | Secondary Heating & Conditioning | The fine particles is conditioned and heated again with chemical agent, so that the oil is stripped off from the solid phase and enters the liquid phase. |

| 5 | Solid Liquid Separation | After heating and conditioning, the oily sludge is pumped to two-phase decanter centrifuge for solid-liquid separation treatment. The solid sludge with oil content of less than 2% can be further biodegraded or processed in pyrolysis or incineration equipment. |

| 6 | 3 Phase Separation | After solid liquid separation, the oily sludge is pumped to a three-phase disc separator for separation to obtain saleable oil, and the usable washing water, and solid is discharged through flushing pump. |

After treated by oily sludge treatment system, the oil is recovered as a resource, the water can be reused for hot washing, and the oil content of the sludge is greatly reduced. Finally, the sludge can be processed for further harmless treatment through biodegradation, thermal analysis, or incineration.