GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

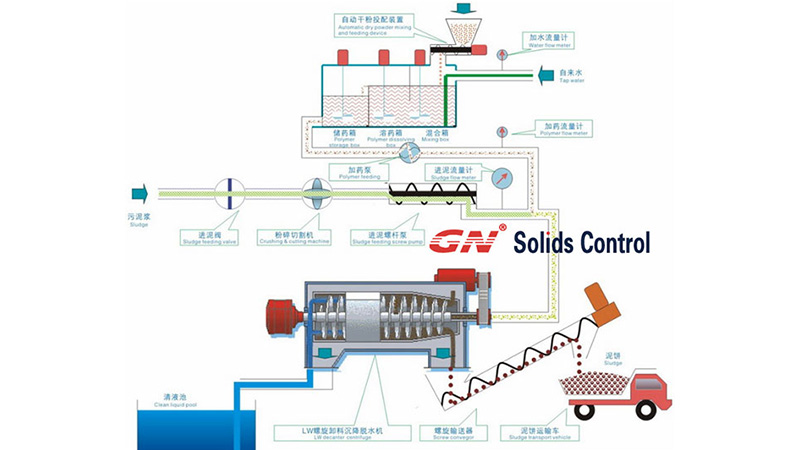

GN Dewatering System includes Chemical Dosing Unit and Dewatering Centrifuge, and it is widely used to separate fine particles in wastewater. For wastewater treatment, simple mechanical separation method can only be used to separate particles of 2-5 microns, but it is difficult to separate finer particles. Ultrafine particles in wastewater can be separated out by using GN Chemical Dosing Unit together with High-Speed Decanter Centrifuge, which can meet customers' separation requirement.

GN Chemical Dosing Unit has features of compact structure, small size, corrosion resistance, low energy consumption, easy operation and maintenance. The Dosing compartment can be used for stirring, dissolving and storage of Flocculent, and then Chemical can be feed to each dosing point by dosing Pump. According to the principle of chemical preparation and customers’ requirement, GN Company can offer two kinds of unit.

GN Company can also optimize and put together of the two unit, and provide customized solutions for clients.

| No | Description | Qty |

|---|---|---|

| 1 | Three-slot cabinet: stainless steel, including dosing hopper, dry powder conveyor, flow meter, mixer, etc. | 1 Set |

| 2 | Dosing Pump (With pump bracket and manifold) | 2Unit |

| 3 | Safety Valve | 2Unit |

| 4 | Back Pressure Valve | 2Unit |

| 5 | Pressure Gauge | 2Unit |

| 6 | Buffer | 2Unit |

| 7 | Filter | 1Unit |

| 8 | Explosion Proof Control Cabinet, PLC Smart Contro | 1Set |

The main box of the Dry Powder Dosing unit is made of stainless steel. The box is divided into three compartments, Preparation Stage, Curing Stage, and Storage Stage.

During the automatic dispensing process, the operator adds the chemical to the chemical preparation tank, then starting the system, the mixture of chemical and water would firstly enters into the Stirring Dissolving Tank, and it would be fully stirred and mixed; When the Stirring Dissolving Tank is full, the chemical would flow to the Curing Dissolving Tank, and stirring and mixing again here; When the Curing Dissolving Tank is full, the chemical would flow to the Dissolved Chemical Storage Tank, and the configured chemical can be feed to the dosing point by the Dosing Pump.

| No | Description | Qty |

|---|---|---|

| 1 | Dissolved Chemical Barrel, PE out covered with Metal Shell or Stainless Steel Shell, Including stirrer, magnetic flap level gauge, etc. | 1Set |

| 2 | Dosing Pump (With pump bracket and manifold) | 2Unit |

| 3 | Safety Valve | 2Unit |

| 4 | Back Pressure Valve | 2Unit |

| 5 | Pressure Gauge | 2Unit |

| 6 | Buffer | 2Unit |

| 7 | Filter | 1Unit |

| 8 | Explosion Proof Control Cabinet | 1Set |

The main body of the Liquid Solvent Dosing Unit includes Mixing Tank and Mixer. Its volume meets the requirement of Liquid Flocculants flow, and the Mix Tank is equipped with electric mixer.

The chemical is pre-configured by the operator and filled into the Mixing Tank by pump. It can also be prepared by manually adding powder chemical into the Mixing Tank and mixing with water in proportion.

GN is able to put the optimized combination of the chemical dosing unit into the renovated container, and connect with external equipment through the reserved manifold connection, and it helps to facilitate operation and transportation. The container-type dosing unit can be transported as a whole. Operators can operate without obstacles inside the container if outdoor environment is terrible.