With the continuous development of construction equipment, GN Separation and Conveying equipment is being used more and more widely. In the field of construction equipment, GN Shale Shaker, Decanter Centrifuge, Screw Conveyor, Solids Vacuum Pump, Mud Centrifugal Pump are widely used in trenchless HDD projects, TBM or pipe jacking projects, hydraulic vacuum excavation projects, construction waste disposal projects, etc. GN Separation & Conveying can also provide centrifugal mud pump and solids vacuum pump for construction mud transportation. In the field of separation equipment, according to different material particles, GN can provide multi-stage separation and processing equipment, including shale shaker screening separation, hydro cyclone separation, and centrifuge dewatering separation. The ultimate goal is to treat the clients’ construction mud into reusable liquid or drainable water.

Typical Video for Construction Slurry Separation System

Equipment for Construction Industry

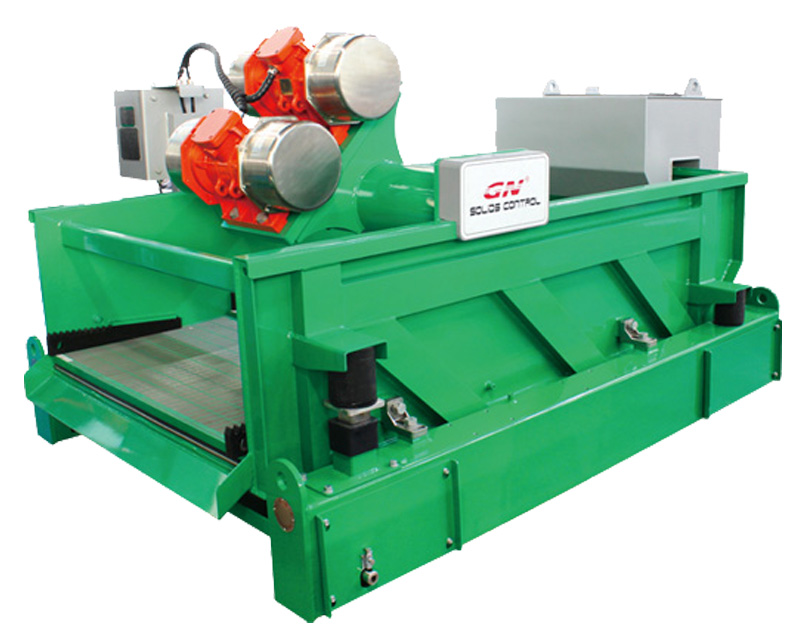

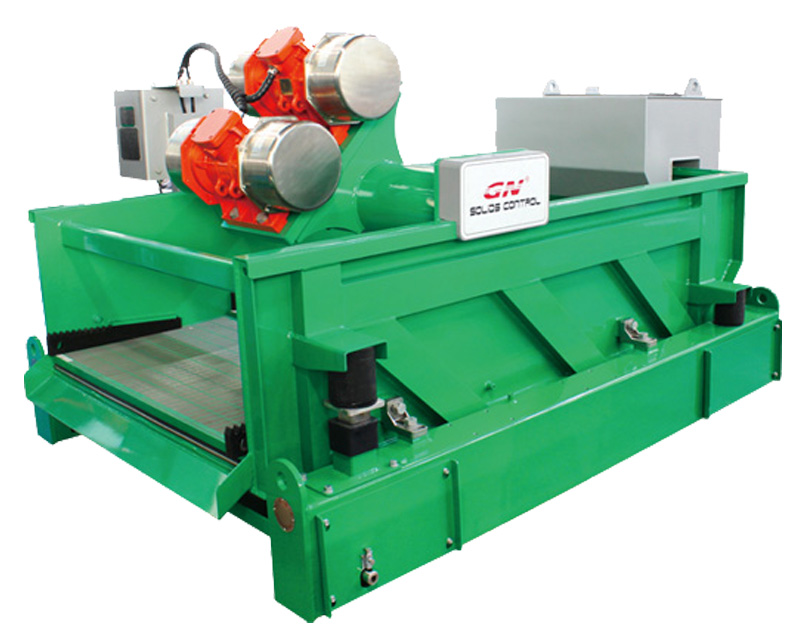

| Vibrating Screen |

GN Vibrating Screen can be used for screen-separation of coarse solid particles in construction mud or construction waste. According to working condition, users can choose single-layer vibrating screen or double-layer vibrating screen, and cyclone can be equipped on vibrating screen to perform hydrocyclone separation. |

|

| Decanter Centrifuge |

GN Decanter Centrifuge uses high-speed rotating centrifugal force, with G force up to 3000G, which can concentrate and dewater construction mud. Comparing with Filter Press, Decanter Centrifuge has advantages of small footprint, high degree of automation, and easy operation. With the chemical dosing unit, the decanter centrifuge can achieve more thorough construction mud dewatering effect. |

|

| Slant Plate Clarifier |

GN Slant Plate Clarifier is also widely used for construction mud treatment. Its working principle is that the solid particles falling to the surface of the slant plate, and then falling down to the sludge collection trough by gravity. The clarified wastewater flows out via outlet at the top of the Slant Plate Clarifier. The slant plate clarifier is of large handling capacity and low cost; but the discharged solid is high moisture, which requires further dewatering treatment. |

|

| Screw Conveyor |

GN U-type Screw Conveyor and Tube Type Screw Conveyor are widely used in transportation of bulk materials in the construction industry: including cement, lime, construction waste, etc. According to client requirements, shafts and shaft-less screw conveyors are available. |

|

| Solids Vacuum Pump |

GN Solids Vacuum Pump is a pneumatic pump with strong self-priming ability, vacuum degree up to 25 inches of mercury, and long discharge head. It can transport solids, liquids, and solid-liquid mixtures. The solids vacuum pump can be widely used for mud suction, mud transportation, and long-distance transportation of bulk materials in the construction industry. |

|

| Centrifugal Mud Pump |

GN Centrifugal Mud Pump is unlike ordinary centrifugal water pumps, it can transport mud with solid content up to 20%. |

|

| Chemical Dosing Unit |

GN Chemical Dosing Unit is used to prepare chemical flocculant for sewage treatment, including flocculant PAM, coagulant PAC and other chemical agents. It is automatic mixing and dosing of chemical agents, together with GN separation equipment to make a mechanical separation and chemical separation combination solution, which can be widely used in construction mud treatment projects. |

|

Construction Industry Common Application

| Trenchless/HDD |

Trenchless Horizontal Directional Drilling rig is a construction machine that used for laying of various underground utilities (pipes, cables, etc.) without digging on the ground surface. It is widely used in the construction of flexible pipelines, including water supply, electricity, telecommunications, natural gas, coal gas, oil. It is suitable for sandy soil, clay, and other conditions, while it’s not suitable for the places where the groundwater level is high or the pebble formation. It works in the most areas of non-hard rock in China. GN can provide horizontal directional drilling mud recovery system, mud mixing system, and waste mud dewatering treatment system. |

| TBM and Pipe Jacking Construction |

The Mud Pressurized Shield Construction Method is to inject mud into the sealed compartment of the excavation surface, with balance of mud pressure and external pressure to ensure the stability of the soil at the excavation surface. During the processing, the excavated soil enters into the mud chamber at the front of the tunneling machine, stirred by a stirring device. The mixed high-concentration mud is pumped to the ground by mud pump; after separation on the ground, the mud is sent back to mud chamber of the tunneling machine for continuous solids removal and purification. GN can provide complete mud separation system for TBM. Shale shaker is used to separate the coarse particles, and desander & desilter are used to separate sand and silt, and decanter dentrifuge is used to separate ultrafine particles in TBM processing. |

| Piling Project |

Piling project is a construction method to smash wooden or stone piles into the ground to make the building foundation solid with special machine. The common construction methods are driving, pressing, vibrating or screwing the piles of various materials into the ground. And the specified methods are hammering, vibration, water injection and pile pressing. Under some working conditions, in order to assist the piling construction, the bentonite mud will be injected. GN mud treatment equipment, including shale shaker, cyclone, and decanter centrifuge, can be widely used for mud separation processing to achieve mud recycling, or environmental treatment of waste mud. |

| Hydraulic Vacuum Excavation |

Hydraulic Vacuum Excavation is the non-destructive digging of the ground through high-pressure water together with high-level vacuum suction by vacuum truck. Hydraulic vacuum excavation really achieves safe and non-destructive excavation, small excavation area, remote construction, high efficiency, low cost, only one operator required, and effective prevention of safety accidents. The waste mud produced by hydraulic vacuum excavation can be processed by GN separation equipment to recover stones, sand, fine soil and clear water. The solid material can be used as building material, and water can be reused for hydraulic vacuum excavation. |