It is well known that beneficiation is an important link in the process of mineral production. Beneficiation is the process to separate useful minerals from gangue minerals by electric separation, gravity separation, flotation, magnetic separation and other methods after crushing and grinding the ore according to the physical and chemical properties of different minerals in the ore, and separate various symbiotic (associated) useful minerals from each other as much as possible to remove or reduce harmful impurities, of obtaining raw materials for smelting or other industries. In the application of beneficiation and coal preparation industry, it is inseparable from solid-liquid separation equipment. GN equipment can provide mining vibrating screen for screening separation, decanter centrifuge for centrifugal separation, solid vacuum pump and screw conveyor for mineral transportation. In the field of beneficiation and coal preparation, GN mining vibrating screen can be used for screening and classification of beneficiation materials, dewatering and demineralization of minerals, etc. According to the screening particle size, GN mine vibrating screen includes coarse screen and fine screen, and is divided into medium screen and large screen according to the size and treatment capacity. GN decanter centrifuge is multifunctional equipment in beneficiation and coal preparation industry - especially in mineral solid-liquid separation and tailings dewatering treatment. GN solid vacuum pump and screw conveyor play an important role in the transportation of minerals in beneficiation and coal preparation industry.

GN Mining Business- Vibrating Screen and Centrifuge Equipmment

EQUIPMENT FOR MINING INDUSTRY

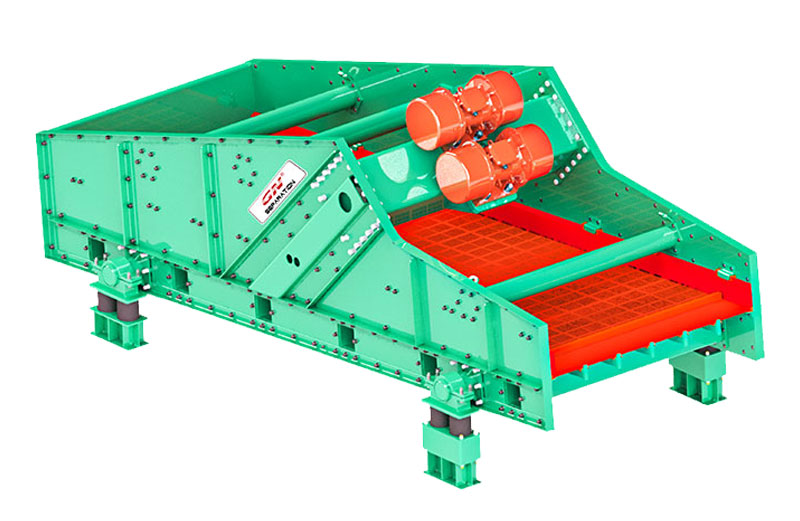

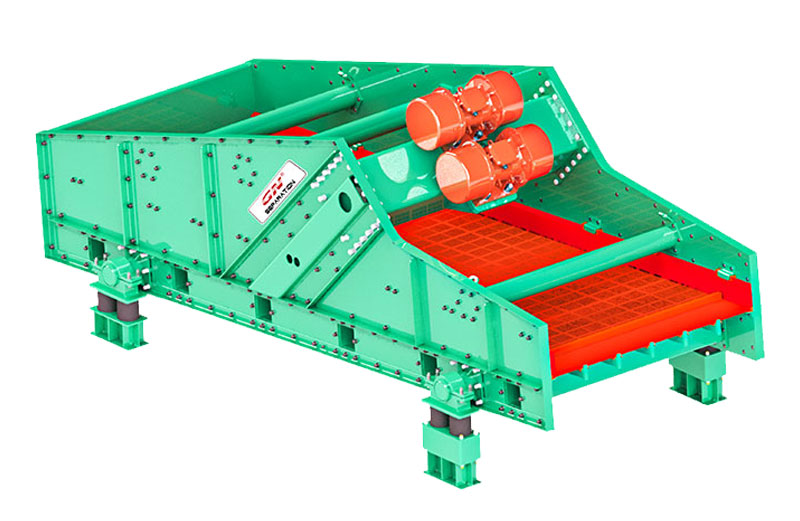

| Medium Mining Vibrating Screen |

GN medium-sized mining vibrating screen is divided into coarse screening and high-frequency fine screening. The coarse vibrating screen has medium-sized dewatering vibrating screen and medium-sized classification vibrating screen, and its screen area ranges from 4.3m2 to 11.5m2. This covers all mainstream application models. The fine screen is divided into single-layer high-frequency fine screen and stack vibrating screen. The stack vibrating screen is from 2 layers to 5 layers. |

|

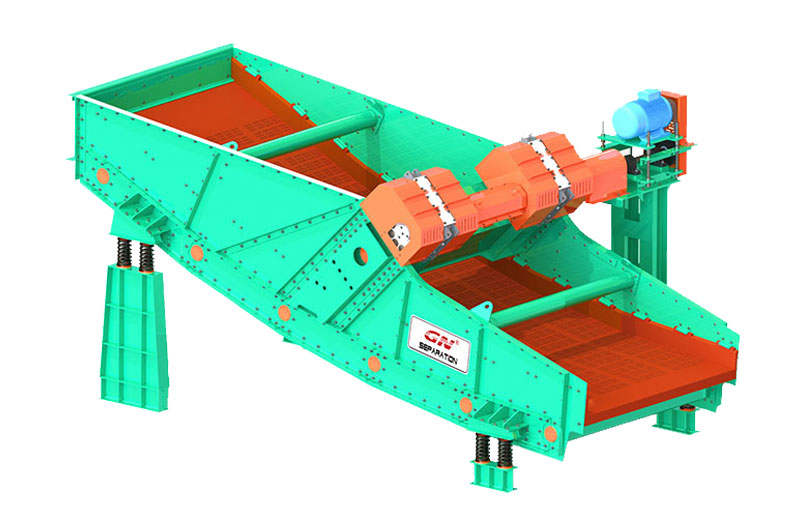

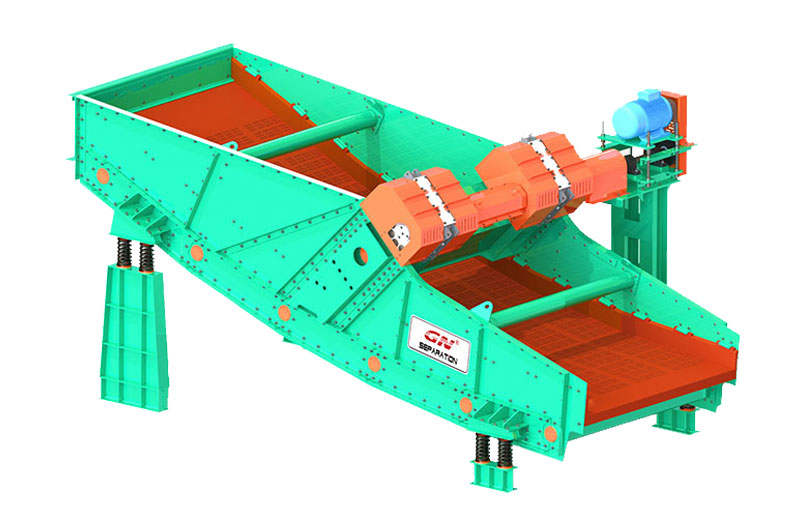

| Large Mining Vibrating Screen |

GN Large mining vibrating screen includes large linear vibrating screen, large banana screen and large flip-flow screen. Its screening area ranges from 11.6m2 to 31.5m2, covering products with different sizes and processing capacity requirements. Large mining vibrating screen can be made into single-layer screen or double-layer Screen. GN large mining vibrating screen can meet the capacity requirements of a single equipment with large processing capacity and reduce the process flow and operation cost. |

|

| Decanter Centrifuge |

GN decanter centrifuge uses high-speed rotating centrifugal force, the G force can reach 3000G. It is widely used in solid-liquid separation of minerals, mineral concentration and mining tailing dewatering. The decanter centrifuge in the mining industry usually adopts more advanced wear-resistant technology to extend the service life of the decanter centrifuge in mineral separation and mining tailing dewatering. Compared with the filter press, the decanter centrifuge is of smaller footprint, high degree automation, and simple operation. |

|

| Solids Vacuum Pump |

GN solids vacuum pump is a pneumatic pump with strong self-priming ability, vacuum degree up to 25 inches of mercury, and discharge head up to 80 meters. It can transport solids, liquids, and solid-liquid mixtures. GN solids vacuum pumps are widely used in the mining industry for mineral suction, mud transportation, and long-distance transportation of bulk materials. Unlike other rotary conveying pumps, GN solids vacuum pump has no rotating parts; therefore, it has better wear resistance in mineral transportation. |

|

| Screw Conveyor |

GN screw conveyor, also known as auger conveyor, is widely used in the transportation of bulk materials in mining and beneficiation industries: including coal mine, porcelain clay, calcium carbonate, titanium dioxide, barite, zinc sulfate, aluminum hydroxide, metal minerals, etc. |

|

| |

MINING INDUSTRY COMMON APPLICATION

| Ore Treatment |

The ore treatment technology is very diverse and is becoming more and more important. Especially in the production of precious metals and base metals, ore treatment plays a key role. In this technology, GN separation and conveying equipment is applied in different ore treatment areas of the mining industry: iron ore, lead ore and zinc ore, gold ore, silver ore, nickel ore, copper ore, platinum ore, lanthanide elemental ore. |

| Minerals Treatment |

Minerals have a large number of application possibilities and treatment methods: from the ceramics industry to the cosmetics and coatings industry, from simple machining to the use of chemical processes, everything is possible. The minerals treatment widely uses GN separation and conveying equipment: coal mine, porcelain clay mine, bentonite, calcium carbonate, barite mine, titanium dioxide, zinc sulfate, aluminum hydroxide and other minerals. GN mining vibrating screen is used for the front-stage screening and dewatering of minerals, and the decanter centrifuge is used for the solid-liquid separation of minerals or the dewatering treatment of tailings. Unlike other companies that only provide standard equipment, GN can also provide complete mineral conveying and separation systems. |

| Tailings Treatment |

With the increasing emphasis on environmental protection all over the world and the scarcity of water resource, every country has continuously improved tailings treatment technology in the mining industry. In the exploration of metal mining, the slag discharged after extracting has formed a large number of tailings. With the expansion of the production scale, the tailings accumulation has increased year by year, not only occupying a large amount of land, polluting the atmosphere, surface water and groundwater, but also causing a huge safety hazard to the tailings stock as many tailings ponds are overdue or overloaded. At the same time, the construction and maintenance of tailings warehouses also request a lot of money, so tailings treatment is an urgent matter currently. The core equipment for tailings treatment is decanter centrifuge. The continuous separation treatment of tailings by decanter centrifuge has obvious advantages over magnetic separation, floating separation, and gravity separation. Its advantages are: pollution-free, low energy consumption, large treatment capacity, obvious effect on fine-particle materials, small footprint, and wide application range. |

| Coal Washing |

In the process of coal washing in the coal preparation plant, it is very important to classify the coal and dewatering the slime. GN can provide coarse screening and fine screening for the coal preparation industry. In addition, GN decanter centrifuge can also be used for ultra-fine coal slime dewatering and tailings treatment. |