GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

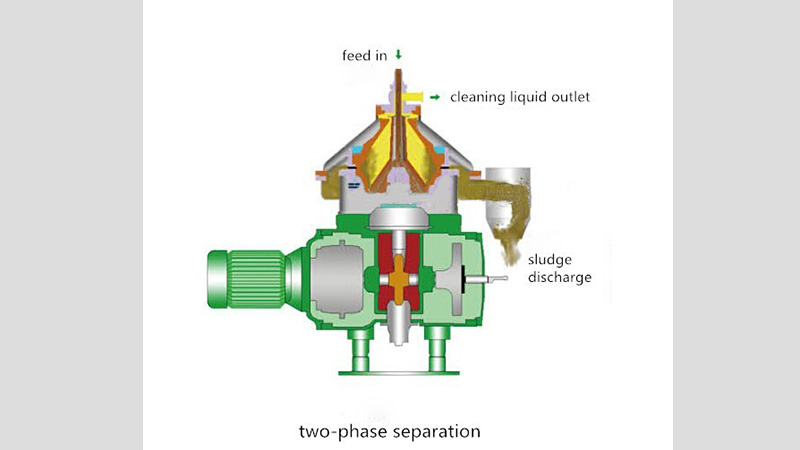

The 2 phase disc stack separator is used to separate the fine particles from the liquid and discharge clarified liquid. Compared with decanter centrifuge, the G force of 2 phase disc stack separator is much higher than decanter centrifuge. The disc stack separator G force is up 12000g. Generally, the G force of the decanter centrifuge is about 3000G. The high speed and G force makes the disc stack separator to produce high clarified liquid. However, the materials separated by disc separator should not have high solid content or big particles. Usually the particles content should be less than 3%, it’s better to be 1%. Therefore, in some application, pre-treatment will be carried out by decanter centrifuge or other separation equipment, and then clarification and separation will be carried out in the 2 phase disc stack separator. The 2 phase disc stack separator is widely used in vegetable oil clarification, biological and chemical pharmaceutical industry, dairy and beverage industry, biofuel and marine oil clarification, etc.

The material to be clarified enters the bowl through a feed pipe. In the distribution cabinet of the disc separator, the material is smoothly accelerated until it is synchronized with the speed of the rotary bowl. The disc stack in the rotating cylinder divides the material into many thin layers, forming a large area of clarification area. The high-speed centrifugal force makes the solid slag separated from the liquid in the disc stack deposit into the solid slag collection cavity at the edge of the bowl. The self-discharging 2 phase disc separator can be adjusted according to the material.

| Model | GNLD-40 | GNLD-90 | GNLD-125 | GNLD-225 |

| Type | Solid-Liquid Separation(Liquid Clarification) | |||

| Bowl Diameter | 440mm | 580mm | 620mm | 800mm |

| Sliding Piston | 380mm | 500mm | 550mm | 700mm |

| Max Capacity | 1-2 m3/h | 5-10m3/h | 10-15 m3/h | 20-25m3/h |

| Max Speed | 7100RPM | 6150RPM | 6000RPM | 4500RPM |

| Max G Force | 12409G | 12273G | 12488G | 9063G |

| Motor Power | 11KW | 18.5KW | 30KW | 45KW |

| Feeding Pressure | 0-0.1Mpa | |||

| Starting Time | 10-15Minutes | |||

| Feeding Material | Solids content less 3% | |||

| The above specification and parameters for reference only. | ||||