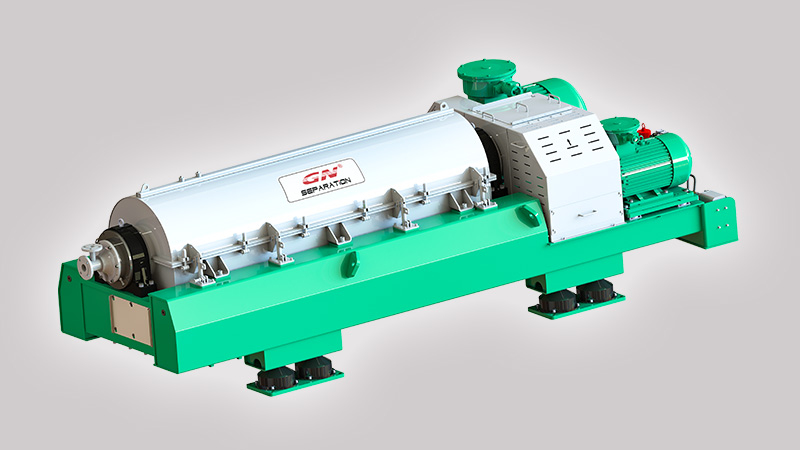

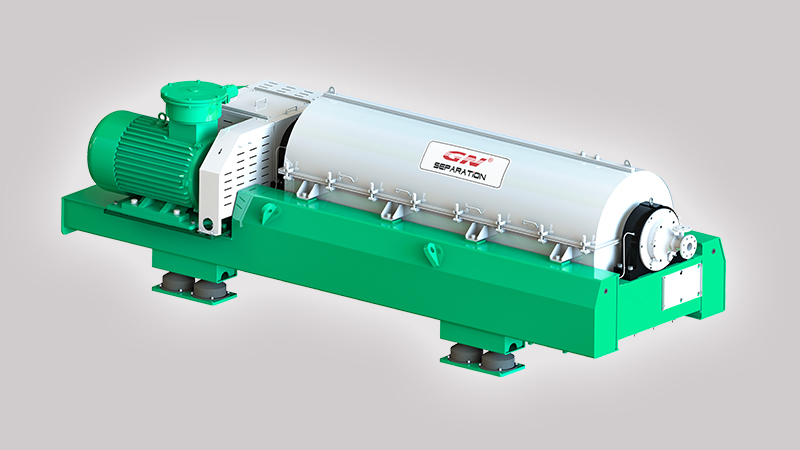

GN Separation Decanter Centrifuge is Y series decanter centrifuge with beach angle of 15 degree. GN Separating Decanter is a centrifuge in which the clarified and separated light weight liquid phase is gravity discharged on the decanter's liquid side while the heavy liquid phase leaves the decanter together with the solids. In order to meet the comprehensive requirements of customers for solid-liquid two-phase separation, the separation decanter is designed not only for the clarity of liquid phase after separation, but also the dryness of solid phase. Y Series separation decanter centrifuge is especially suitable for fine soft material separation. It is usually used in soft materials which are difficult to separate. It suits for material of small particles, small density difference in solid-liquid, large viscosity and small concentration.

Applicable Material for Separation Decanter:

Biological pulp, yeast solution, animal and plant protein recovery, yeast recovery, grape juice, soybean milk, plant starch recovery, fermentation liquid, distiller's grains liquid recovery, baths, ultrafiltration residues, low concentration activated sludge, juice by-products, saponifia produced in oil refining process, recovery of vitamins and enzymes, further extraction of plant raw materials, etc.

Y series Separation Decanter Centrifuge Specification

| Model | GNLW-

224GY | GNLW-

364GY | GNLW-

454GY | GNLW-

554GY | GNLW-

654GY | GNLW-

764GY |

|---|

| Bowl Diameter |

220 mm

(9 Inch) |

360 mm

(14 Inch) |

450 mm

(18 Inch) |

550 mm

(22 Inch) |

650 mm

(25.6 Inch) |

760 mm

(30 Inch) |

| Bowl Length |

941 mm

(37 Inch) |

1520 mm

(59.8 Inch) |

1880 mm

(74 Inch) |

2310 mm

(91 Inch) |

2730 mm

(107.5 Inch) |

3160 mm

(124.4 Inch) |

| Max Speed |

5054 RPM |

3964 RPM |

3437 RPM |

3112 RPM |

2864 RPM |

2650 RPM |

| Max G Force |

3200 G |

3200 G |

3000 G |

3000 G |

3000 G |

2900 G |

| Bowl L/R Ratio |

4.2 |

4.2 |

4.2 |

4.2 |

4.2 |

4.4 |

| Main Motor |

11 KW |

22/30/37 KW |

37/45/55 KW |

55/90 KW |

90/110 KW |

110/132/160 KW |

| Back Motor |

5.5 KW |

7.5/11 KW |

11/15/22 KW |

15/37/45 KW |

18.5/22/37/55 KW |

22/37/75/90 KW |

| Beach Angle |

15° |

| Remark |

- The T-Series, Y-Series, C-Series decanter are interchangeable by replacing bowl assembly.

- Final specifications should be based on commercial and technical offer.

- The handling capacity of decanter centrifuge with same size under different working and material condition varies greatly, please consult GN for details.

|

| The above specification and parameters for reference only. |

Y series Separation Decanter Centrifuge Features

- The beach angle 15 degree of Y series separation decanter centrifuge is between 8.5 degrees of T Series and 20 degrees of C series. Therefore, Y Series separation decanter centrifuge integrates the separation advantages of T series dewatering decanter centrifuges and C series clarifying decanter centrifuges.

- Y series Separation Decanter Centrifuge can be designed and manufactured according to the health requirements applicable to the food and pharmaceutical field to meet the requirements of washing and health protection in the food and pharmaceutical field.

- The shaft caps on the two ends and the bowl are made of duplex stainless steel SUS2205 or SUS2304 by centrifugal casting, which is superior to the performance of SUS304 and SUS316. The main parts are made by centrifugal casting and die forging process to avoid intergranular corrosion and incomplete residual stress release caused by traditional welding process.

- The screw blade is pressed by the CNC spiral blade forming equipment. Compared with the traditional drawing screw blade, it has higher slag conveying efficiency than the traditional drawing screw blade.

- According to the material properties, the screw blade can adopt gradual change type, which can obviously improve the efficiency of screw’s transport and press force to make the solids dryer.

- Optimized beach angle and pitch, large beach angle and medium pitch with BD baffle plate make the dewatering zone separated from the sedimentation zone. The depth of the liquid pool is deeper and the dewatering zone is longer. The separated clear liquid is more clear and dry, and the processing capacity is larger. The deep liquid pool loses less kinetic energy when the clear liquid is discharged. The machine consumes less energy and is more energy efficient. At the same time, it has a material acceleration structure to reduce turbulence in the bowl to make the liquid more clear, reduced turbulence makes the screw flight discharge port better protected for anti-abrasion, so the screw conveyor has a longer service life.

- For special high-concentration and high-viscosity materials, a double cone design can be used, that is, the cone drum has two beach angles. The double beach angle greatly improves the resistance of slag discharge, and increases the treatment capacity under the condition of increasing the slag dryness and liquid clarity.

- The wear-resistant sleeve of the solid discharge port is a special hard tungsten carbide sleeve, of which the wear resistance is extremely high, and not fragile.

- The overflow weir plate has a convenient and flexible design for adjusting the depth of liquid pool to meet the requirements of dryness and wetness and clarity of materials under various working conditions.

- The collection box cover of the small model is assisted to open by a gas spring, and it can support and protect safety.

- The large model adopts a labor-saving lid opening device, and a single person can lift the lid of the collection box, reducing the labor intensity of workers and facilitating equipment maintenance.

- Each type of main bearing is designed with hydraulic disassembly structure, which reduces the tension required to remove the main bearing by 90%, and reduces the risk of damage to the bearing itself and the high precision parts when the bearing is removed.

- After each main rotary parts are machined by high precision CNC equipment, the centrifuge is treated with three dynamic balance processing again, including the 1800RPM medium speed dynamic balance in the main rotary body component, the actual working speed high speed dynamic balance and the whole machine balance, so as to ensure the stable operation of the centrifuge under the high speed working condition.

- The screw propeller is protected by replaceable wear-resistant alloy plate with long service life and easy maintenance.

- Some models adopt the open-type screw blade, greatly enhancing the centrifuge processing capacity. Screw propeller utilizes stainless steel, after high temperature solution treatment, not easy to deform, good corrosion resistance, good strength stiffness, and long service life.

- Two motors are arranged at one end of the centrifuge saving much space; the structure is compact for the operation and maintenance of the centrifuge, while avoiding the accident of the motor damage caused by the material leakage at the inlet end.

- Main bearing adopts premium SKF series high-end bearings with long service life. Depending on the user's choice, it can also be equipped with an automatic lubrication system.

- The grease lubrication system for the main bearing of the small model can be equipped with a semi-automatic or fully-automatic batch grease lubrication system, which can provide full and reliable lubrication for the main bearing, reduce the labor intensity of the workers and improve the service life of the bearing.

- The main bearing of the large machine adopts the oil injection automatic circulation lubrication system, which has the function of cleaning and cooling the main bearing, and the service life of the main bearing is greatly improved.

- With complete machine monitoring and alarm system. When overload, short circuit and lack of phase occur in the course of operation, the centrifuge will be automatically protected; the speed of centrifuge, bearing temperature, vibration of the whole machine, lubrication system oil pressure, main and back motors’ current, push torque and other operating parameters are monitored in real time, and alarm is started when the parameters are abnormal. In case of blocking materials, the device will automatically switch to the plugging procedures; if plugging procedures cannot be dredged, it will then automatically switch to the shutdown procedures to ensure the safety of personnel and equipment.

- Usually adopts stainless steel electric control panel equipped with world famous VFD, PLC, HMI and other electric components. According to user requirements, GN can also provide VFD control panel with explosion-proof certificates home and abroad, such as China's CNEX explosion-proof, ATEX explosion-proof and IECEX explosion-proof.

GN can not only provide customers with Y Series Separation Decanter Centrifuges widely used in the industrial field, but also provide transfer pumps and conveying machine used in separation projects. GN can also provide high-speed disc separator for customers to separate materials with higher clarity requirements.