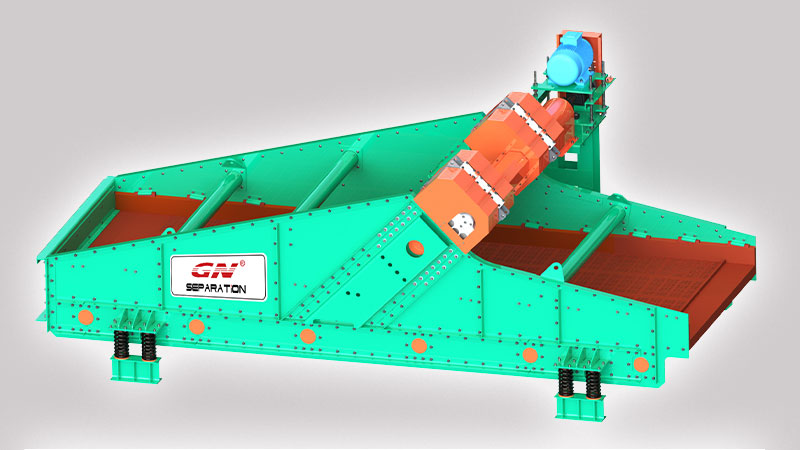

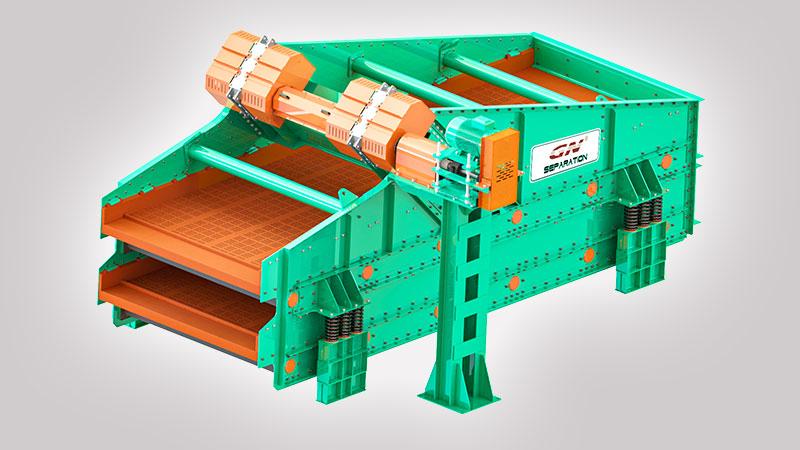

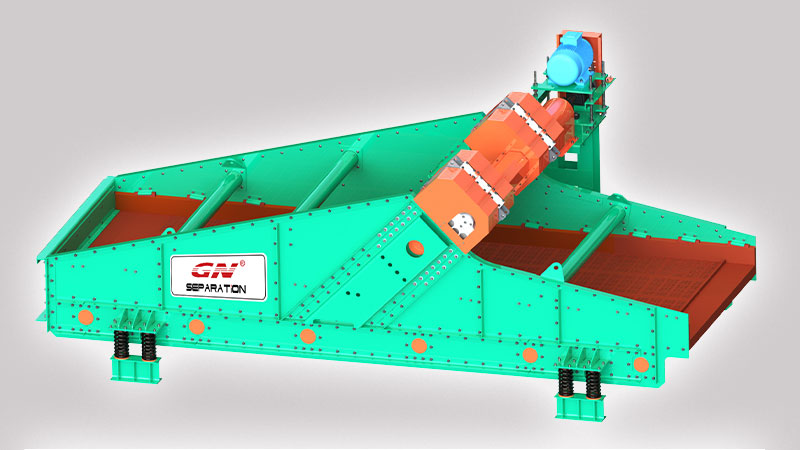

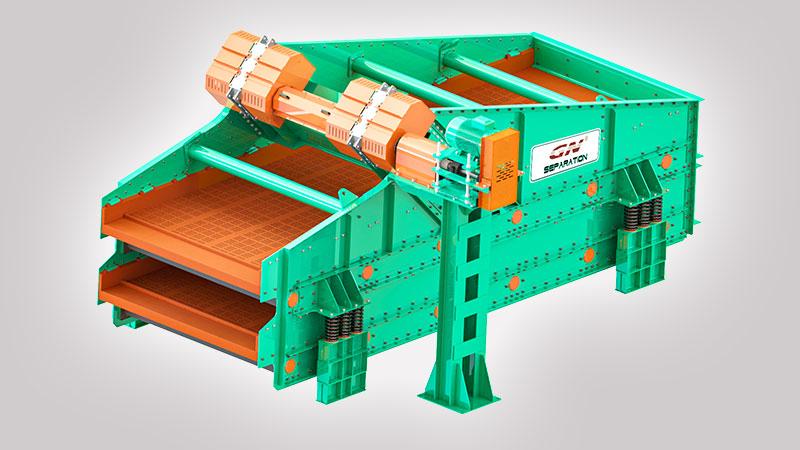

GN large linear vibrating screen is mainly composed of box type vibration exciter, screen box, vibration damping spring, support and driving device, and the running amplitude track is linear. The screen machine can be arranged horizontally or at an inclined angle. It is widely used in wet classification, dewatering, demineralization, tailings dry discharge and other process links in mineral processing, coal preparation, gravel aggregate, building materials, chemical industry and other industries. The screen surface structure is generally divided into single layer or double layer. The model of screen unit can be customized according to customer requirements.

Large Linear Vibrating Screen (Single Deck)

| Model | GNLS2461 | GNLS3061 | GNLS3661 | GNLS3673 | GNLS4361 | GNLS4373 |

|---|

| Screen Area m2 |

14.64 |

18.3 |

21.96 |

26.28 |

26.23 |

31.39 |

| Vibration Direction Angle° |

45 |

| Vibration Frequency Hz |

14~16 |

| Power kW |

30 |

30 |

45 |

45 |

55 |

55 |

| Double Amplitude mm |

7~10 |

| Mesh Size mm |

0.2~25 |

| Capacity t/h |

60~240 |

80~300 |

100~480 |

100~700 |

120~800 |

120~900 |

| Installation Inclination° |

0 |

| Remark |

- The above parameters are for reference only and can be adjusted according to the customer's situation. The final quotation and technical agreement shall prevail.

- The handling capacity of materials with the same size and different working conditions varies greatly. Please consult GN company for details.

|

Large Linear Vibrating Screen (Double Deck)

| Model | GNLD2461 | GNLD3061 | GNLD3661 | GNLD4373 |

|---|

| Screen Area m2 |

14.64×2 |

18.3×2 |

21.96×2 |

31.39×2 |

| Vibration Direction Angle° |

45 |

| Vibration Frequency Hz |

14~16 |

| Power kW |

30 |

55 |

55 |

90 |

| Double Amplitude mm |

7~10 |

| Mesh Size mm |

0.2~25 |

| Capacity t/h |

80~350 |

80~460 |

100~750 |

120~950 |

| Installation Inclination° |

0 |

| Remark |

- The above parameters are for reference only and can be adjusted according to the customer's situation. The final quotation and technical agreement shall prevail.

- The handling capacity of materials with the same size and different working conditions varies greatly. Please consult GN company for details.

|

Features and Advantages of GN Large Linear Vibrating Screen :

- The screen machine wallboard is not welded, and the plate is made of high-strength alloy steel plate with better impact toughness. The imported Huck rivets are used for hydraulic tension assembly. This advanced design makes the wallboard free of welding residual stress.

- Through finite element analysis, optimize the structure and vibration parameters of the screen, avoid the natural frequencies of all levels of the screen, reduce the influence of resonance, and extend the service life of the whole machine.

- The cross beam under the screen adopts rectangular tube design; The exciting beam box structure is designed with light weight, high strength and good toughness. The post welding heat treatment process of main components can effectively eliminate welding stress.

- The surface of the beam is sprayed with polyurea by a spray machine imported from the United States. The parts that are easy to impact and wear can also be protected by rubber parts, which are resistant to erosion and wear.

- High efficiency helical gear box type exciter, with super large exciting force, ultra-low noise, stable operation and long service life; The eccentric block is arranged outside the exciter box, so that the amplitude can be adjusted by changing the counterweight setting.

- Product serialization to meet the production requirements of customers under different process conditions; Polyurethane screen panel is modular, more versatile and more convenient to replace.

Large Linear Vibrating Screen Working Principle

- GN large linear vibrating screen is equipped with two gear box vibrators, which make the screen body move back and forth in a linear motion by using the principle of forced synchronization.

- Under the action of exciting force, the screen machine drives the screen surface to vibrate synchronously, and transmits the force to the materials on the screen, so as to impact the materials to be thrown up on the screen surface for layering and screening and grading according to the specified particle size.

- The materials are continuously buffered and input from the feeding trough to the receiving plate, screened and graded through the screen surface, and the materials on and under the screen are discharged into the receiving trough on and under the screen respectively, entering the next process link.

- The included angle between the direction of the exciting force and the level can be designed according to the properties of the materials on the customer's site. This included angle determines the running speed of the materials on the screen surface and the processing capacity of the equipment.