GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

During coal mine operations, significant quantities of coal and rock dust are generated across key stages, including roadway tunneling, coal extraction, and dust suppression. This particulate matter is carried by mine water and accumulates in underground water sumps, gradually forming high-concentration, high-viscosity sludge deposits.

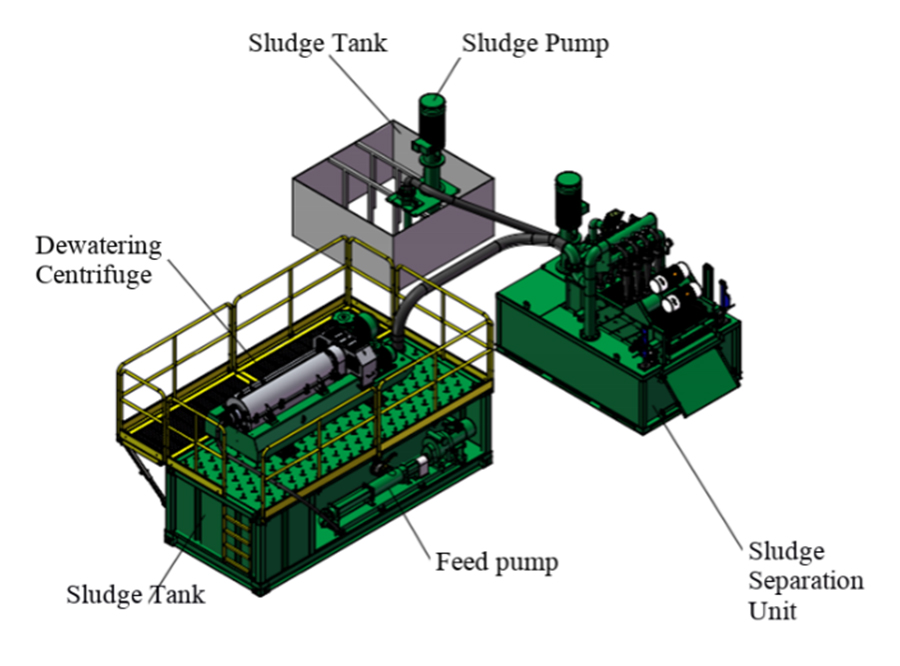

The Coal Sump Sludge Dewatering System is a mechanized, automated solution engineered to treat dense sludge buildup in underground central sumps, mining area sumps, or temporary drainage points. Its primary function is to facilitate sludge-water separation, transforming unmanageable liquid sludge into dry sludge cakes and clean, reusable water.

This process effectively eliminates the need for manual sump dredging, ensures unobstructed mine drainage, and supports safe, efficient, and eco-friendly mining operations. Typically featuring a modular design, the system allows for easy transportation, installation, and relocation to enable mobile use.

1. The sludge pump pumps the slurry to the bottom screen of the vibrating screen for screening. The oversize (solid material) is discharged with the vibration, while the undersize slurry falls into the collection tank of the sludge separation unit.

2. The feed pump of the sludge separation unit conveys slurry to the desilter for treatment. The high-concentration solid underflow separated by the desilter is discharged onto the upper deck of the vibrating screen for dewatering, while the separated liquid overflow from the desilter flows into the dewatering centrifuge tank.

3. The feed pump of the centrifuge sludge tank transfers slurry to the dewatering centrifuge, which then efficiently separates fine solid particles from the slurry.

4. Based on actual operating conditions, a chemical flocculant may be added to the slurry prior to its entry into the dewatering centrifuge. This addition enhances flocculation, facilitates the separation of ultrafine solid particles, and allows the centrifuge to generate clear, reusable water.

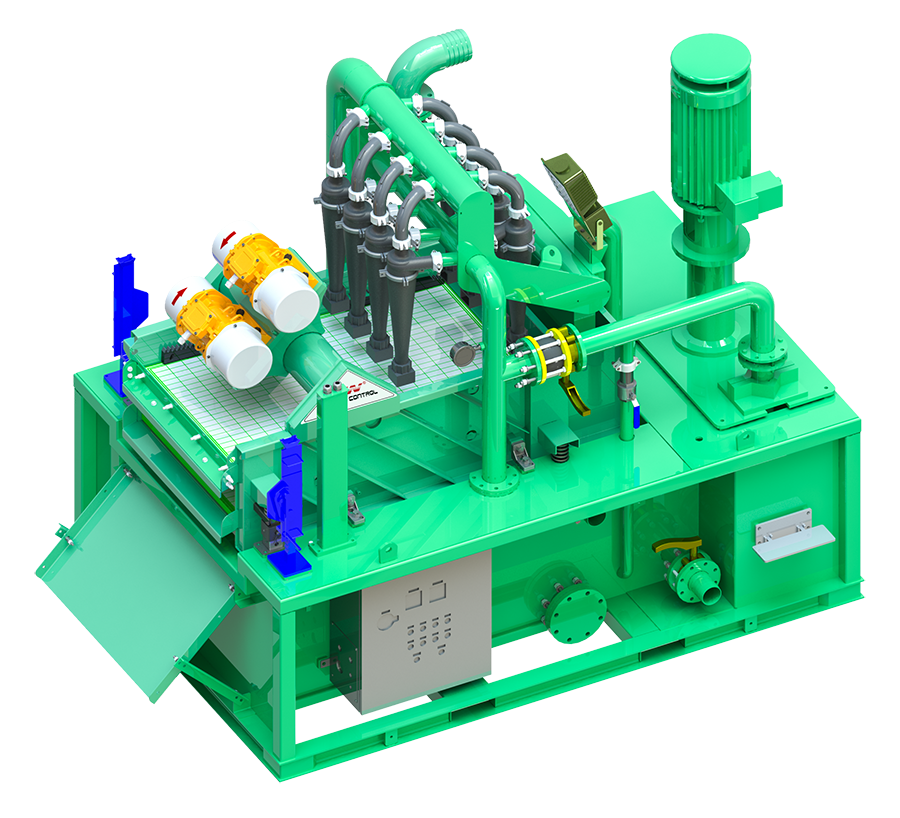

| Sludge Separation Unit | This equipment is an integrated Sludge Separation system, featuring a compact structure, high separation efficiency, and convenient transportation. It is composed of a Double-deck High-frequency Shale Shaker, Desilter, Submersible Pump, and Collection Tank. By selecting and configuring different hydrocyclones and feed pumps, the system can handle various processing capacities.

|

|

|

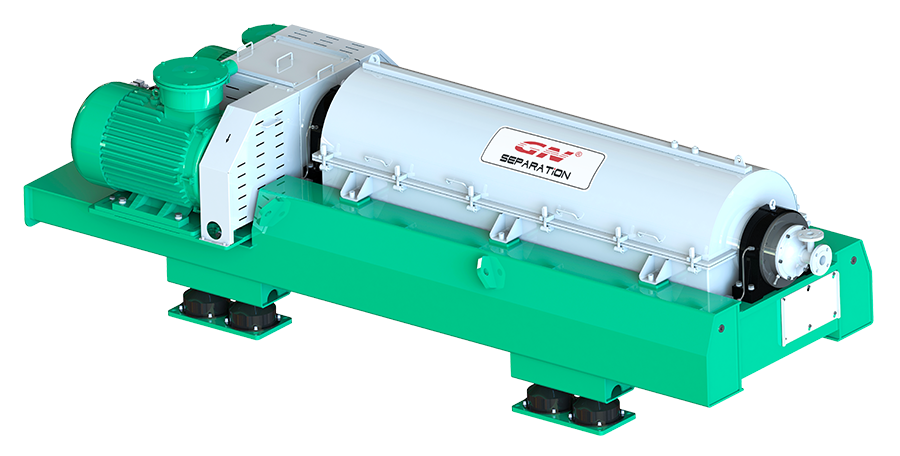

| Sludge Dewatering Centrifuge | The sludge dewatering centrifuge efficiently separates solids and liquids through a high-speed rotating bowl and a screw propeller. Under strong centrifugal force, solids settle quickly and are discharged from the conical end, while clean water flows out from the opposite side. This design ensures continuous operation, high efficiency, and reliable performance in sludge treatment.

|

|