GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

GN Dewatering Vibrating Screen is widely used in the mining ...

GN Classification Vibrating Screen is widely used in the ...

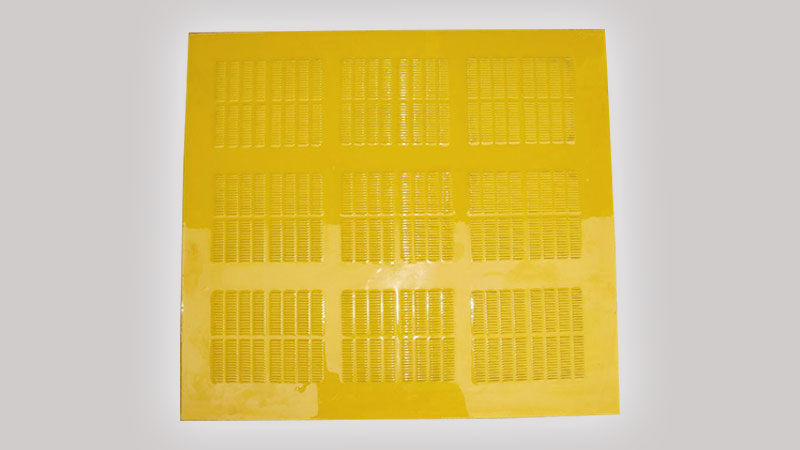

GN Polyurethane Screen Panel is commonly used in dewatering ...

Polyurethane screen mesh is often used to adapt to Fine ...

| Polyurethane Screen Panel-Coarse Screening | Screen Panel Opening 0.2-30mm |

|

It is made of polyurethane wrapped metal skeleton. It is characterized by good wear resistance and strong corrosion resistance. The disadvantage is that it is not resistant to high temperature and the conductance is general. |

| Metal Gap Screen Panel-Coarse Screen | Screen Panel Opening: 0.2-30mm |

|

It is welded by stainless steel screen bar, and the hole type is wedge-shaped hole, which is not easy to be blocked. Various opening specifications can be customized, with high temperature resistance and good conductance. The disadvantage is that it is not suitable for ultra-fine particle screening. |

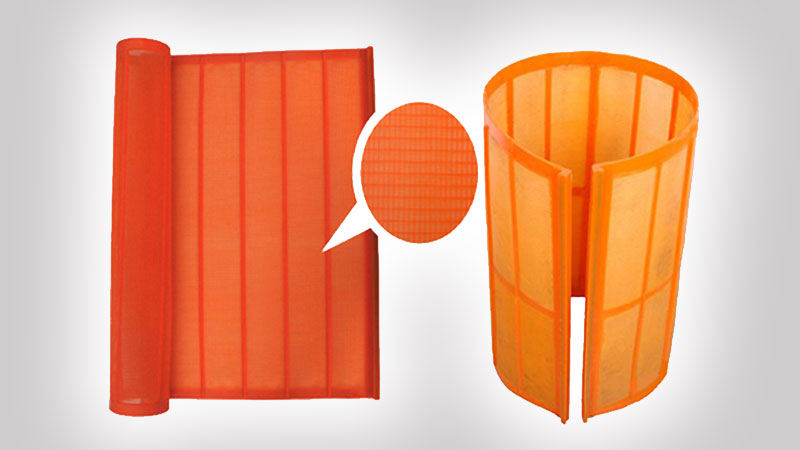

| Polyurethane Screen Mesh-Fine Screen | Screen Panel Opening:0.045-2mm |

|

Fine screen polyurethane screen mesh is a kind of polymer polyurethane elastomer, which has excellent physical and mechanical properties: high strength, high elasticity and high wear resistance. The opening rate of polyurethane screen with different mesh is 28% ~ 45%. Conductance is not good as the stainless steel wire mesh. |

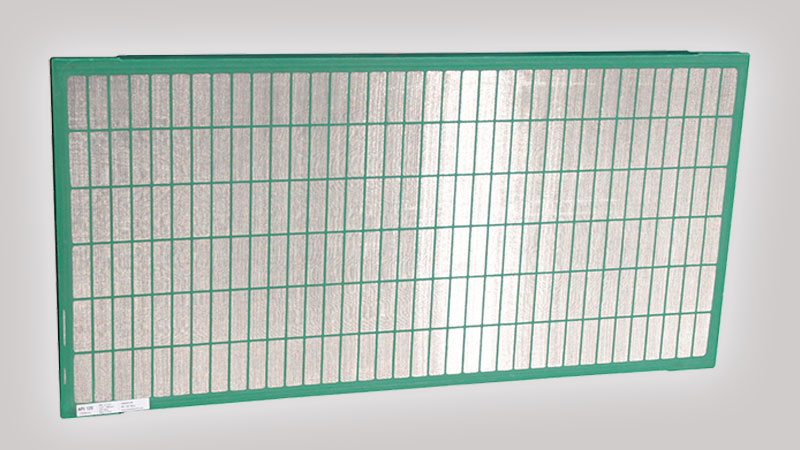

| Stainless Steel Wire Mesh Screen-Fine Screen | Screen Panel Opening 0.038-2 mm |

|

It is made of stainless steel wire and then hot pressed and bonded to the support frame. It is characterized by being able to screen ultra-fine particles, good conductance and not easy to block the mesh. The disadvantage is that the wear resistance is weak. |