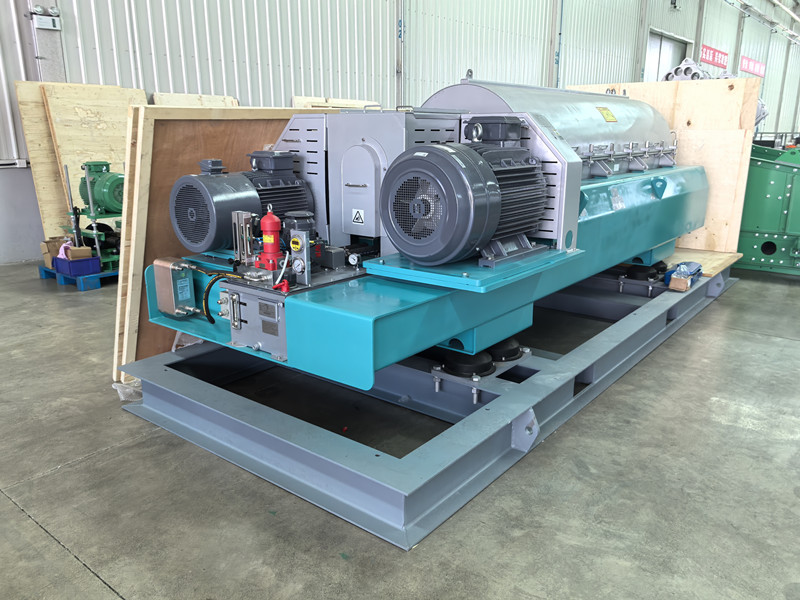

GNLW654 Decanter Centrifuge Ready for Shipping to European Client

Recently, GN Separation has successfully completed factory acceptance testing of one set GNLW654 Decanter Centrifuge. The unit, engineered with its features for enhanced operational flexibility and durability, is now preparing for shipment to a key client in Europe.

Dual-Motor Drive System: Precision Control for Dynamic Environments

At the core of the GNLW654 dewatering centrifuge superior performance lies its dual-motor drive configuration, a design that enables operators’ flexibility to fine-tune both the main bowl rotational speed and the differential speed between the bowl and screw propeller, optimizing separation efficiency across diverse process conditions. Whether handling viscous slurries, abrasive tailings, or fluctuating feed compositions, the dual-motor system ensures rapid adaptation to material variations, minimizing downtime and maximizing throughput.

Continuous Lubrication: Ensuring Reliability Under Pressure

To guarantee uninterrupted operation in demanding 24/7 environments, the GNLW654 incorporates a fully automated thin-oil lubrication system. Unlike grease-lubricated alternatives, this closed-loop design continuously circulates oil to both main bearings, effectively dissipating heat and preventing premature wear. By maintaining optimal lubrication levels even under extreme loads, the system extends bearing lifespan, reducing maintenance frequency and lifecycle costs.

Tungsten Carbide Wear Protection: Engineering for Longevity

Recognizing the abrasive nature of slurry processing, GN Separation has equipped the GNLW654’s rotating assembly with tungsten carbide wear plates and liners at high-contact zones. These hard components, renowned for their resistance to erosion and corrosion, shield vulnerable areas such as the screw flights and feed zone from degradation. The result is a dramatic extension of mean time between failures, with some clients reporting longer service intervals for wear parts.

Synergy with Flocculation Dosing Systems: Optimizing Separation Efficiency

The GNLW654’s capabilities are further amplified when paired with GN Separation’s chemical dosing units, creating a holistic solution for solids-liquid separation challenges. In wastewater treatment, the centrifuge works in tandem with polymer dosing systems to enhance particle aggregation, enabling efficient removal of suspended solids and biological sludge.

In mining applications, the combination proves equally transformative. By pre-treating tailings pulp with flocculants, the GNLW654 achieves higher solids capture rates, critical for sustainable tailings management. Recent field trials of GN tailing dewatering centrifuge at a copper mine in Mexico demonstrated a reduction in solids content of clarified tailing slurry, significantly reducing the waste disposal.

Global Impact: From Municipal Plants to Mining Giants

In recent years, GN Separation’s decanter centrifuges have earned a reputation for reliability across industries. The GNLW654, with its modular design and scalable capacity, is already generating interest from European municipalities seeking to upgrade aging wastewater infrastructure and mining corporations aiming to modernize tailings processing.

As GNLW654 prepares for its transcontinental journey, GN Separation reaffirms its commitment to advancing separation technology. The company focuses on durability and process integration, and is ready to continue supporting customers to achieve cleaner and more efficient operations.