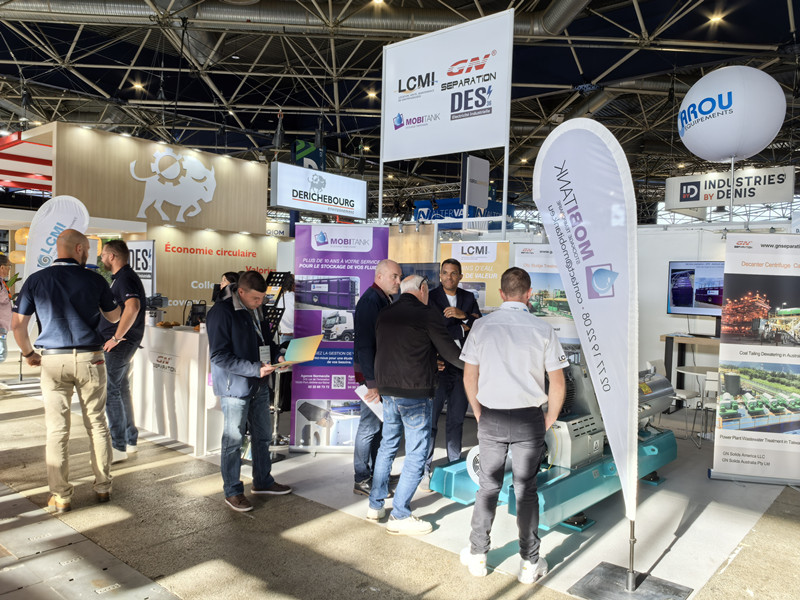

GN Separation is showing at Pollutec 2025 in Lyon, France

Lyon, France – This week, GN Separation is showing at Pollutec 2025, Europe’s premier environmental exhibition, held in Lyon. In collaboration with its French partner, the company has secured a prominent booth to showcase two flagship sludge dewatering machines: the Decanter Centrifuge and the Screw Press Unit. These solutions underscore GN Separation’s commitment to delivering high-performance, cost-effective technologies that align with stringent environmental regulations.

Decanter Centrifuge: Precision, Efficiency, and Adaptability

The Decanter Centrifuge stands out as a powerhouse in sludge dewatering, leveraging centrifugal force to separate solids from liquids with unparalleled efficiency. Designed for high-capacity operations, this technology excels in industries such as municipal wastewater treatment, chemical processing, and food production, where rapid throughput and consistent dry solids content are critical.

Key Advantages:

1. High Processing Capacity: Capable of handling large volumes of sludge up to over 100 m³/h according to different models, the Decanter Centrifuge ensures continuous operation, reducing downtime and operational costs.

2. Superior Separation Efficiency: By adjusting rotational speeds and differential speeds, operators can fine-tune the machine to achieve optimal solids capture and dryness, minimizing disposal costs.

3. Compact Footprint: Ideal for space-constrained facilities, the Decanter’s design integrates seamlessly into existing treatment plants.

Screw Press Unit: Low-Maintenance, Cost-Effective Dewatering

For smaller-scale operations or applications prioritizing simplicity, the Screw Press Unit offers a robust alternative. Combining a slow-rotating screw with a fixed ring structure, the screw press gradually thickens and dewaters sludge without complex mechanical parts.

Key Advantages:

1. Low Energy Consumption: Operating at minimal power, the screw press reduces electricity costs versus centrifuges.

2. User-Friendly Design: With fewer moving parts, maintenance is straightforward, lowering long-term operational expenses.

3. Stable Performance: The screw press consistently produces around 20% dry solids, even with fluctuating feed concentrations, making it ideal for wastewater and food processing byproducts.

4. Quiet Operation: Low noise level ensures compliance with workplace safety standards in urban areas.

Tailored Solutions for Diverse Needs

GN Separation emphasizes that the choice between Decanter Centrifuges and Screw Press depends on project-specific factors, including sludge volume, desired dryness, budget constraints, and space availability. For high-capacity municipal plants or industries with strict discharge standards, the Decanter Centrifuge offers unmatched efficiency. Conversely, the screw press is perfect for smaller facilities or sites where simplicity and low maintenance are priorities.

A Vision for Long-Term Cooperation

GN Separation’s participation at Pollutec reflects its strategy to deepen roots in the European market. By collaborating with local partners, the company aims to co-develop solutions that address regional challenges, such as aging infrastructure and tightening EU water directives. These solutions underscore GN Separation’s commitment to delivering high-performance, cost-effective technologies that align with stringent environmental regulations.