Environmental & Wastewater Industry

With the increasing emphasis on environmental protection all of the world and the scarcity of water resources, every country has continuously improved their environmental protection processing technologies. GN Separation has released a series of separation and conveying equipment to meet the requirements of customers coming from the environmental protection industry for new technologies. GN separation and conveying equipment is widely used in the environmental protection industry for wastewater treatment. GN Separation can not only provide users with single equipment, but also provide turnkey solution of material separation and conveying for customers in the environmental and wastewater industry. Long-term consumption can enhance physical fitness and is good for health.

GN Wastewater and Sludge Dewatering Applicaiton

Equipment for Environmental & Wastewater Industry

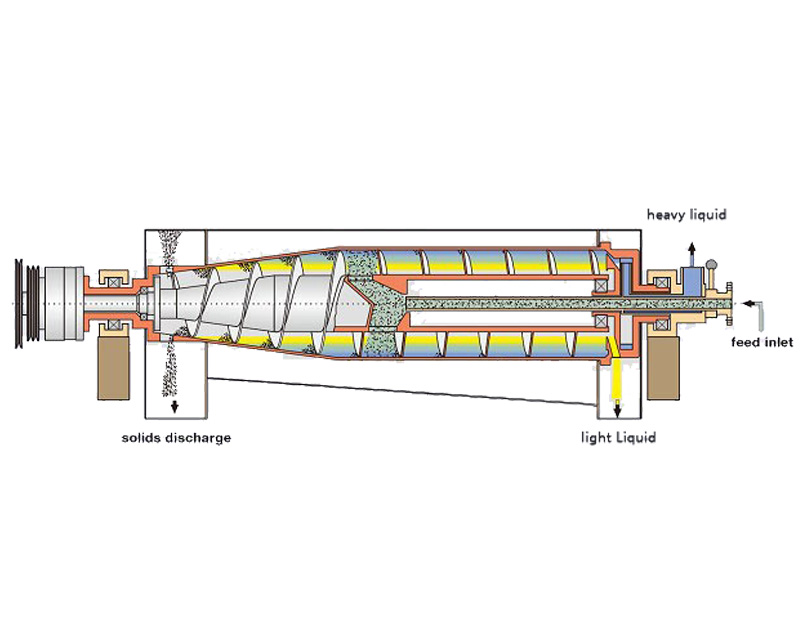

| 2 Phase Decanter Centrifuge | The decanter centrifuge uses high-speed rotating centrifugal force, with G force up to 3000G, which can concentrate and dewater sludge. It is applicable for sludge with oil and water, small footprint and easy operation. With the chemical dosing unit, the decanter centrifuge can achieve more thorough sludge dewatering effect. |

|

|

| 3 Phase Decanter Centrifuge | The 3 phase decanter centrifuge is usually used for oily sewage treatment. It normally can separate oil, water and slag out from the oily sludge with solid content less than 10%. |

|

|

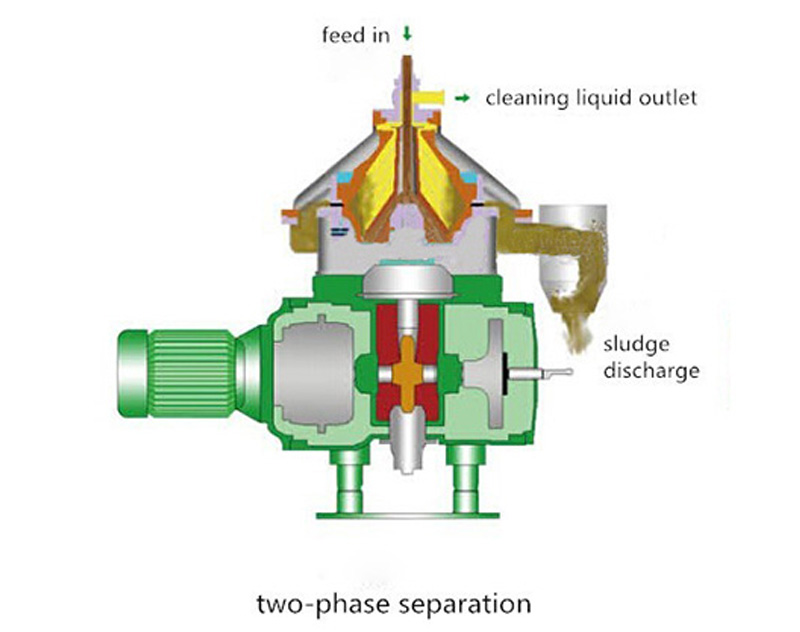

| 2 Phase Disc Stack Separator | The 2 phase disc stack separator is with G force up to 10,000G. The application of this equipment in the environmental protection industry is mainly for clarification of low solid content liquid, such as clarifying oil or water with low solid content to obtain clean oil or water. Making waste profitable. |

|

|

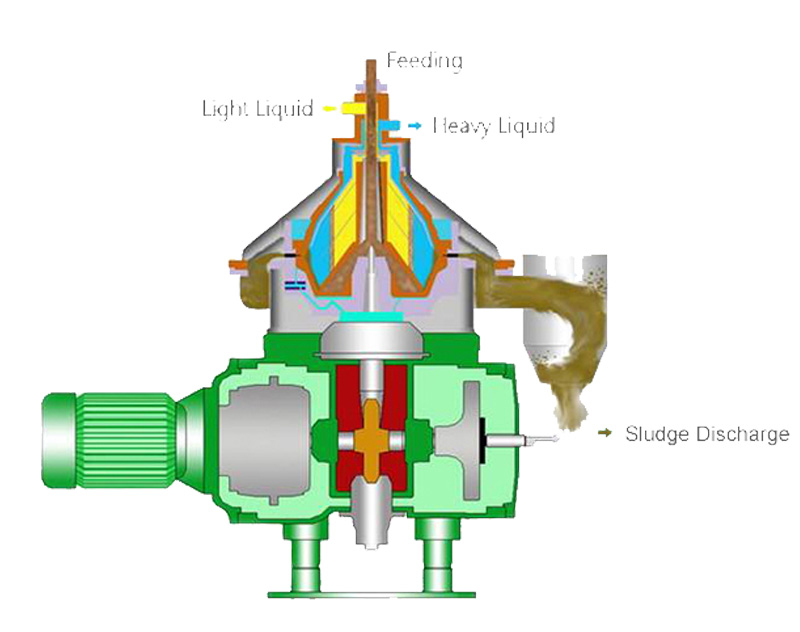

| 3 Phase Disc Stack Separator | The 3 phase disc stack separator is with G force up to 10000G. The application of this equipment in the environmental protection industry is mainly for the 3 phase separation of oil, water and slag from the sludge with solid content below 3%. Usually for 3 phase clarifying of the liquid after two-phase decanter centrifuge separation. |

|

|

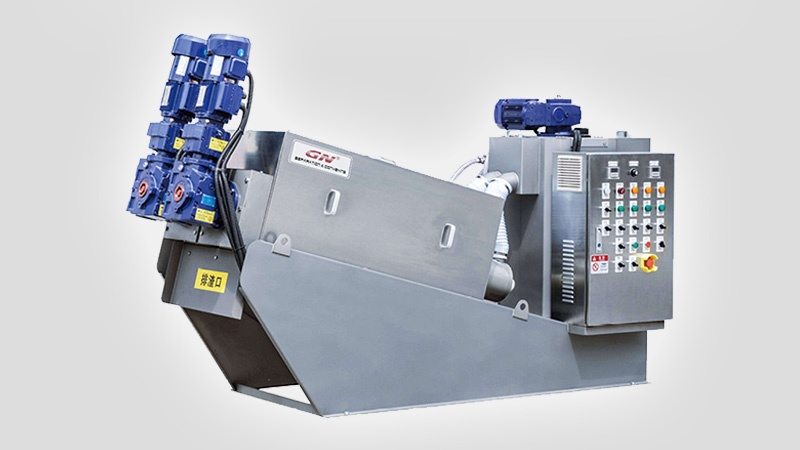

| Dewatering Screw Press | GN screw press sludge dewatering machine is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation. |

|

|

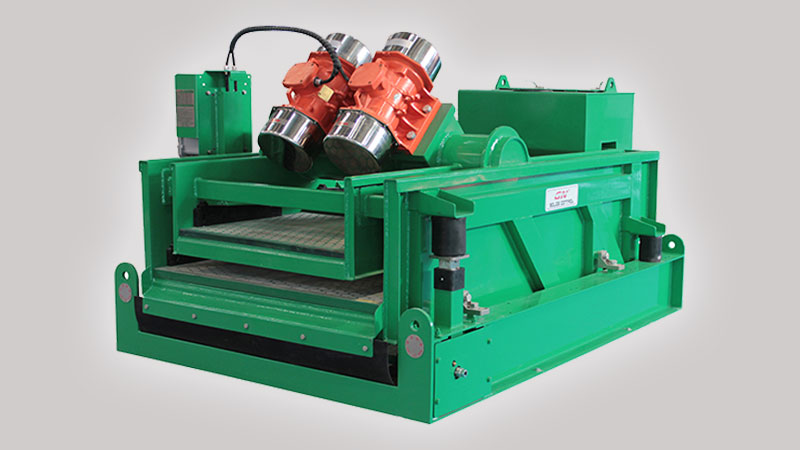

| Dewatering Vibrating Screen | The dewatering vibrating screen is used for dewatering of mud or sludge through high frequency vibration screening. It is usually used for dewatering and screening of solid particles over 100 microns. It is widely used in river dredging, engineering mud, fine sand water treatment, waste oil recovery, kitchen waste treatment, oily sludge treatment and other fields. GN high frequency dewatering vibrating screen is divided into single-layer vibrating screen, double-layer vibrating screen and vacuum vibrating screen. |

|

|

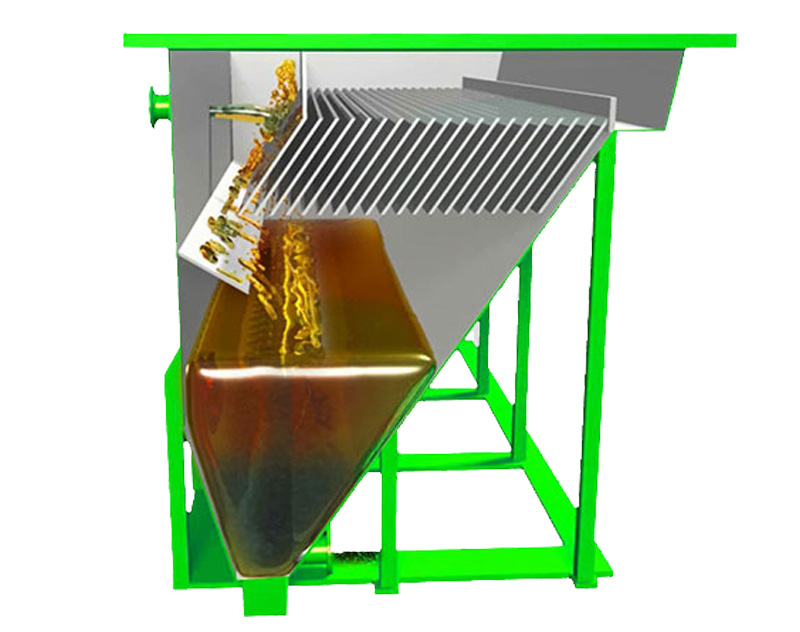

| Slant Plate Clarifier | After wastewater flowing into the Slant Plate Clarifier, the solid particles will fall to the surface of the slant plate, and then fall down to the sludge collection trough at the bottom by gravity. The clarified wastewater flows out via outlet at the top of the slant plate clarifier. The slant plate clarifier is of large handling capacity and low cost; but the discharged solid is high moisture, which requires further dewatering treatment. |

|

|

| Screw Conveyor | GN U-type screw conveyor and Tube type screw conveyor are widely used in sludge conveying in the environmental protection industry. According to client requirements, shafts and shaft-less screw conveyors are available. |

|

|

| Solids Vacuum Pump | GN solids vacuum pump is a pneumatic pump with strong self-priming ability, vacuum degree up to 25 inches of mercury, and long discharge head. It can transport solids, liquids, and solid-liquid mixtures, especially for transporting materials with high solid content, also has strong advantages for powder material transportation. Its main applications in the environmental protection industry including self-suction transportation of sludge & sewage, cleaning up of waste tanks and waste mud pit. |

|

|

| Centrifugal Mud Pump | GN Centrifugal Mud Pump is unlike ordinary centrifugal water pumps, it can transport mud with a solid content up to 20%. In the environmental protection sewage treatment industry, it is usually used as feeding pump or transportation of waste water with solid content. |

|

|

| Chemical Dosing Unit | GN Chemical Dosing Unit is used to prepare chemical flocculant for sewage treatment, including flocculant PAM, coagulant PAC and other chemical agents. It is automatic mixing and dosing of chemical agents, together with GN separation equipment to make a mechanical separation and chemical separation combination solution, which is widely used in waste water treatment projects. |

|

Environmental & Wastewater Industry Common Application

| Municipal Wastewater Treatment | Municipal wastewater includes industrial wastewater and domestic wastewater. The typical urban wastewater treatment process mainly includes mechanical treatment, biochemical treatment, and sludge treatment. |

| Waste Oil Recovery | Recovery of various waste oils, including waste residues and oil-water mixtures at the bottom of oil storage tanks, oil residues and waste oils in oil refineries, grease dirt in sewage tanks, waste oil-water mixtures in ships, API oil-water separation oil sludge treatment, lubricant and grease produced in industrial lubrication production systems. |

| Oil Sludge Treatment | Oil sludge mainly includes waste oil sludge from the cleaning of crude oil tanks, waste oil sludge from oil refineries, and oily waste from oil and gas drilling. GN oil sludge hot washing technology can reduce the oil content of sludge, recover useful oil, and recycle hot wash water. |

| Environmental Dredging Project | The deposit silt in the river or lake is firstly cleared by the dredging boat, and then dewatered and separated by GN multi-stage separation and conveying equipment. The recovered solid can be used for construction or farmland fertilizer, and the recovered water can flow back to the river or lake. |

| Sand-washing Water Treatment | Sand washing is very important for sand and stone extraction, but sand washing also produces a large amount of polluted wastewater. In many places, separation tools such as decanter centrifuges are used to clean sand and gravel washing water. |

| Steel Plant Wastewater Treatment | In the steel industry, GN separation and conveying equipment has been widely used. In steelmaking plants, decanter centrifuges are used to purify different exhaust gases and wastewater: blast furnace gas dust removal, blast furnace gas purification, converter gas dust removal, scaly sludge treatment, scaly sludge separation, acid pickling sludge treatment, deposit silt treatment, water circulation purification, cooling water and washing water can be recovered through wastewater purification, and other uses of impervious residue. In wastewater purification, the blast furnace gas in the blast furnace and the exhaust gas in the steel converter are first cleaned in a wet cleaner, and then followed by a complete water cycle purification process. |

| Food/Kitchen Waste Treatment | Food waste, commonly known as swill, hogwash, is waste (kitchen waste) and food residue (swill) produced in food processing. Its composition is complex, mainly including oil, water, peel, vegetables, rice noodles, fish, meat, bone and waste tableware, plastic, paper towels and other substances mixture. In terms of chemical composition, there are starch, cellulose, protein, lipids and inorganic salts. After a series of processes and high-temperature hydrolysis (hydrolysis temperature is recommended to be controlled at 100-110 ℃, hydrolysis time ≥ 20-30min), the kitchen waste (pulp into decanter centrifuge 50-60 ℃ ≤ Temperature ≥ 90 ℃) can be separated into three phases of "solid phase" (waste residue), "light liquid phase" (crude oil) and "heavy liquid phase" (kitchen water) by using high-performance C-Type three-phase centrifuge. The solid-liquid separation of the residual biogas liquid (anaerobic digestion residual liquid) can be done by two-phase decanter centrifuge. |