| Soy Protein Extraction and separation, Acid Precipitation and Separation |

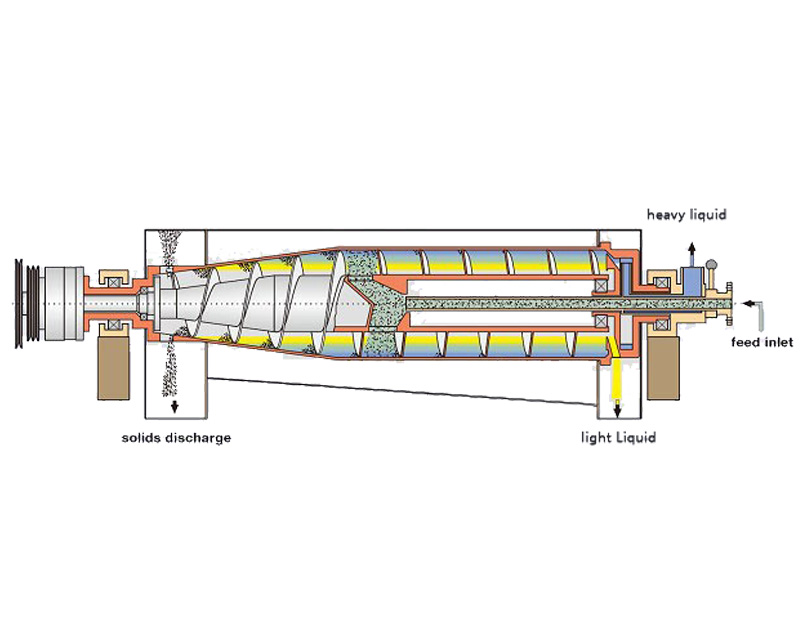

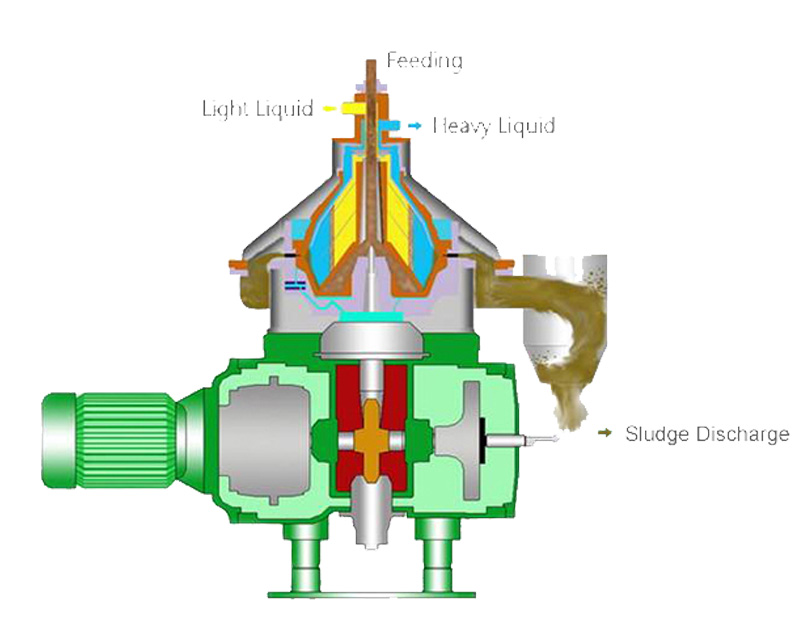

Separation valuable proteins from plants. GN C series high speed decanter centrifuge and disc separator are suitable for each procedure of the protein extraction and acid precipitation. Such as protein extraction, acid precipitation, washing, concentration and clarification. The purpose is to extract as much high quality protein as possible from soybean. |

| Extraction and Recovery of Animal Protein |

Animal protein processing technology: meat scraps crushing, heating, buffer tank, centrifugal separation (Residue: make feed; Liquid: oleoprotein; Liquid: wastewater treatment plant to meet the standard for discharging), centrifugation (Liquid: oleoprotein; Residue: make feed). In the centrifugation process, GN P series 3 phase high-speed decanter centrifuge is used to extract crude fat protein. The obtained crude fat protein needs to be purified and separated by GN 2 phase disc stack separator. The remaining small amount of residue is separated to make the oleosin more pure. |

| Pea Protein Extraction and Separation, Acid Precipitation and Separation |

Pea protein processing technology: cleaning, peeling, crushing, extraction, centrifugation, acid precipitation, centrifugation, desiccation, neutralization, sterilization, flash evaporation, filtration, high pressure homogenization, spray drying, cyclone separation, cloth bag sedimentation, screening, grinding, and finished product packaging. GN high speed C series decanter centrifuge could be used in the procedure of centrifugation after extraction and centrifugation after acid precipitation to separate the pea starch and pea protein; and then GN C series decanter centrifuge and disc stack separator could be used to separate the pea protein and water, bean clear water is discharged to wastewater treatment plant for further treatment then discharged. |

| Potato Protein Extraction and separation |

Potato protein processing technology: juice de-foaming, acid adjustment, preheating, secondary heating, high temperature flocculation, centrifugal extraction, flash drying, filling; in the centrifugal extraction stage, GN high-speed C series decanter centrifuge could be used to separate potato protein from juice with high protein yield and high protein content. |

| Starch Separation and Extraction: potato starch, cassava starch and sweet potato starch |

Potato, cassava, sweet potato starch processing technology: cleaning, disintegration, soaking, secondary disintegration, screening, sand removal, refining, bleaching, concentration, dehydration, drying, packaging, storage; the screening process requires GN GNZS series vibrating screen; GNZJ series de-sanding cyclone separator is required for sand removal process; GN disc separator is used for concentration process, and GN C series high speed decanter centrifuge performs dehydration. The C series high-speed decanter centrifuge makes higher yield of the dehydrated starch with lower water content. It can replace the GK series horizontal scraper filter centrifuge in the old process. |

| Starch Separation and Extraction: wheat starch, pea starch, corn starch, etc. |

Corn, wheat, pea starch processing technology: raw materials, cleaning, soaking, rough grinding, degerming, fine grinding, screening and slag removal, crude starch milk, refined (protein separation), refined starch milk, dehydration, drying, screening, packaging. the screening process requires GN GNZS series vibrating screen; GNZJ series de-sanding cyclone separator is required for sand removal process; GN disc separator is used for concentration process, and GN C series high speed decanter centrifuge performs dehydration. The C series high-speed decanter centrifuge makes higher yield of the dehydrated starch with lower water content. It can replace the GK series horizontal scraper filter centrifuge in the old process. |

| Juice: Apple, pear, jujube, carrot and other fruits, berries and vegetables |

Juice processing technology: fruit selection, cleaning, trimming, crushing, juice extraction, heating, homogenization, clarification, separation, blending, canning, sealing, sterilization, cooling. In the clarification and separation process, GN C series high-speed decanter centrifuge is used for clarification and dehydration. The C series high-speed decanter centrifuge has a remarkable effect on the separation and clarification of fruit juice, high fruit juice clarity, low moisture of fruit residue and high fruit juice extraction rate. |

| Vegetable Oil Separation and Extraction: palm oil, olive oil, sesame oil, sunflower oil, peanut oil and other hair oils |

Vegetable oil processing technology: raw materials, pressing (Slag: make feed, Liquid: virgin oil), heating, separation (Slag: make feed, Liquid: purified oil). In the separation and extraction process, GN C series high-speed decanter centrifuge is used to purify the virgin oil. The separated oil residue has low oil content, high oil yield, higher oil purity and better quality. |

| Production of Alcohol: Beer, Wine, Cider, etc. |

The use of GN separation equipment in the production of alcoholic beverages can increase yields while ensuring stable quality. GN decanter centrifuges and disc stack separators are often used for clarification and extraction separation in the processing of alcoholic beverages. |