GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

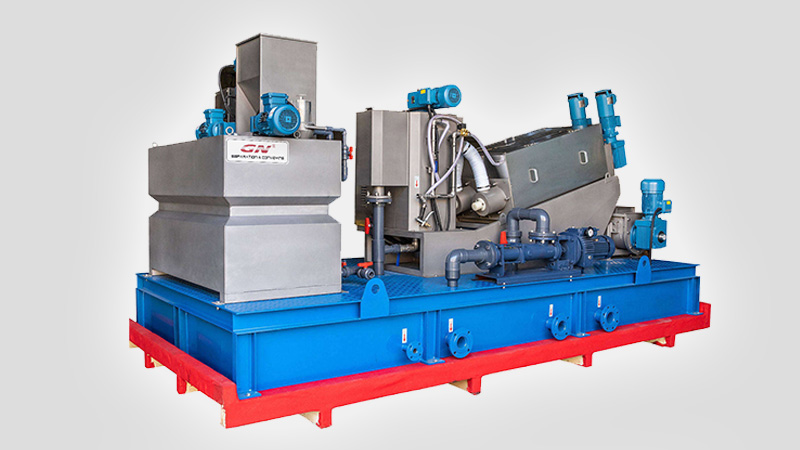

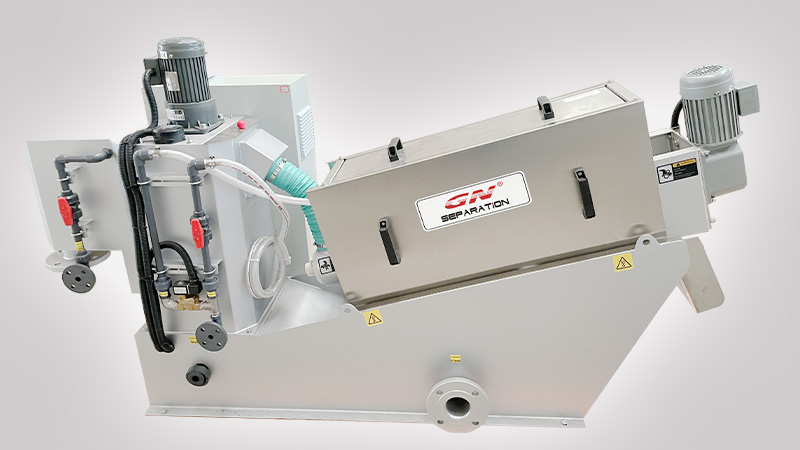

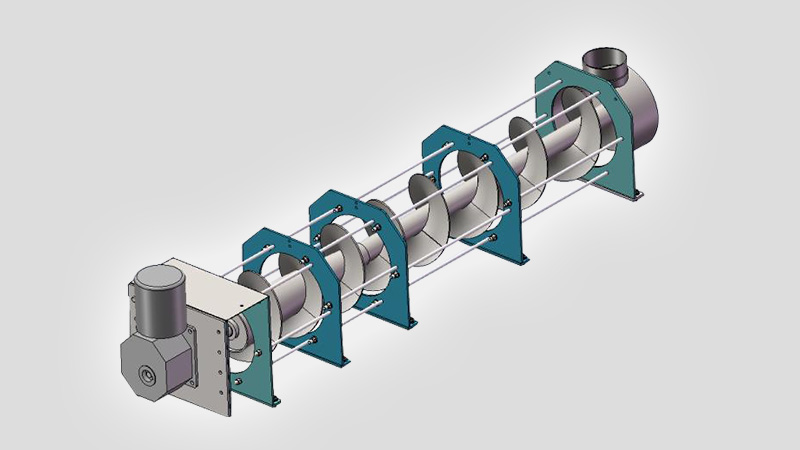

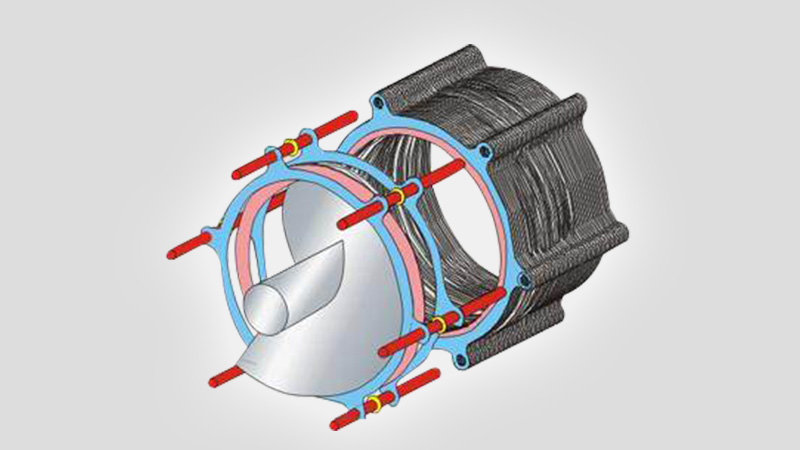

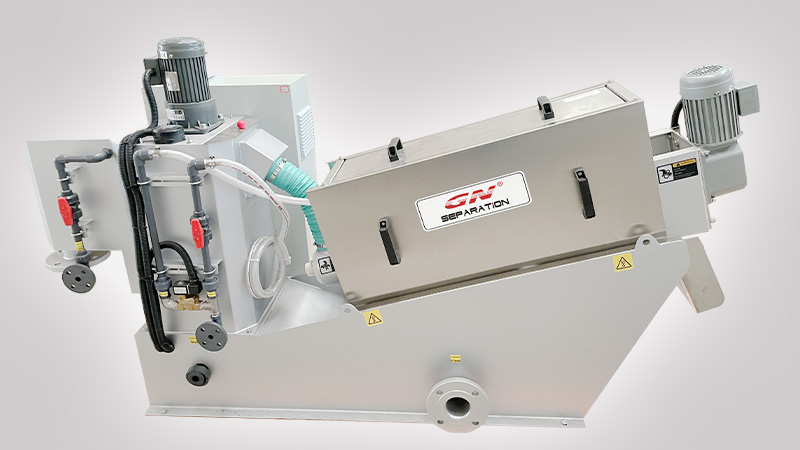

GN screw press sludge dewatering machine is a kind of economic and environmental friendly sludge dewatering equipment. It is a new type of sludge extrusion dewatering equipment by using the principle of screw extrusion, through the strong squeezing force generated by the change of screw diameter and screw pitch, and the tiny gap between the floating ring and the fixed ring, to realize solid-liquid separation. GN dewatering screw press is composed of fully automatic control cabinet, flocculation modulation box, sludge thickening and dewatering device, and liquid collecting tank. GN dewatering screw press is with automatic control technology, which can realize the flocculation fully automatic operation, and continuously complete the sludge thickening and squeezing, finally return or discharge the collected filtrate liquid.

GN screw press dewatering machine is widely used in sewage treatment projects of municipal, aquaculture, food, starch, oil, pharmaceutical, chemical, paper, leather and other industries

| Model | DS Standard Capacity (Absolute Dry Sludge) | Capacity for Sludge with Different Concentration | |||||

|---|---|---|---|---|---|---|---|

| 2000mg/L | 10000mg/L | 20000mg/L | 30000mg/L | 40000mg/L | 50000mg/L | ||

| GNDL131 | 4~14 kg/h | ~2m³/h | ~0.6m³/h | ~0.5m³/h | ~0.4m³/h | ~0.3m³/h | ~0.28m³/h |

| GNDL201 | 8~20 kg/h | ~4m³/h | ~1.2m³/h | ~0.75m³/h | ~0.6m³/h | ~0.5m³/h | ~0.4m³/h |

| GNDL202 | 16~40 kg/h | ~8m³/h | ~2.4m³/h | ~1.5m³/h | ~1.2m³/h | ~1m³/h | ~0.8m³/h |

| GNDL301 | 20~70 kg/h | ~10m³/h | ~3m³/h | ~2.5m³/h | ~2m³/h | ~1.5m³/h | ~1.4m³/h |

| GNDL302 | 40~140 kg/h | ~20m³/h | ~6m³/h | ~5m³/h | ~4m³/h | ~3m³/h | ~2.8m³/h |

| GNDL303 | 60~210 kg/h | ~30m³/h | ~9m³/h | ~7.5m³/h | ~6m³/h | ~4.5m³/h | ~4.2m³/h |

| GNDL401 | 67.5~160 kg/h | ~33.7m³/h | ~10m³/h | ~6.5m³/h | ~5m³/h | ~4m³/h | ~3.2m³/h |

| GNDL402 | 135~320 kg/h | ~67.5m³/h | ~20m³/h | ~13m³/h | ~10m³/h | ~8m³/h | ~6.4m³/h |

| GNDL403 | 200~480 kg/h | ~100m³/h | ~30m³/h | ~19.5m³/h | ~15m³/h | ~12m³/h | ~9.6m³/h |

| GNDL404 | 266~640 kg/h | ~133m³/h | ~40m³/h | ~26m³/h | ~20m³/h | ~16m³/h | ~12.8m³/h |

| The above specification and parameters for reference only. | |||||||

| Model | Screw Diameter | Screw Qty | Screw Power | Agitator Power | Total Power | Flushing Pressure | lushing Water (L/H) | Weight(KG) |

|---|---|---|---|---|---|---|---|---|

| GNDL131 | 130mm | 1 | 0.2KW | 0.2KW | 0.4KW | 0.1Mpa-0.2Mpa(No high pressure flushing device is required) | 20 | 205 |

| GNDL201 | 200mm | 1 | 0.37KW | 0.2KW | 0.57KW | 30 | 290 | |

| GNDL202 | 2 | 0.74KW | 0.2KW | 0.94KW | 30 | 470 | ||

| GNDL301 | 300mm | 1 | 0.55KW | 0.4KW | 0.95KW | 40 | 820 | |

| GNDL302 | 2 | 1.1KW | 0.55KW | 1.65KW | 80 | 1350 | ||

| GNDL303 | 3 | 1.65KW | 0.55KW | 2.2KW | 120 | 1820 | ||

| GNDL401 | 400 | 1 | 1.1KW | 0.55KW | 1.65KW | 70 | 1990 | |

| GNDL402 | 2 | 3KW | 0.75KW | 3.75KW | 140 | 3310 | ||

| GNDL403 | 3 | 4.5KW | 1.1KW | 5.6KW | 210 | 4380 | ||

| GNDL404 | 4 | 6KW | 0.75KWx2 | 7.5KW | 280 | 6170 | ||

| The above specification and parameters for reference only. | ||||||||

| Type | Screw Press | Filter Press | Decanter Centrifuge |

|---|---|---|---|

| Images |  |

|

|

| Energy Consumption | Low | Moderate | High |

| Labor Intensity | Low | High | Low |

| Footprint | Low | High | Low |

| Automation Degree | High | Low | High |

| Investment | Low | High | High |

| Sludge Moisture Content | High | Low | Moderate |

| Operating Cost | Low | Moderate | Moderate |

| Capacity | Low | High | High |

| Capacity for Oily Sludge | Moderate | Low | High |

GN has a complete range of sludge dewatering equipment. Clients can choose the best sludge dewatering equipment according to different sewage treatment targets and investment budgets. In addition, GN can also provide integrated mobile sludge dewatering solution according to customer requirements.