GN China

- Phone:+86-13731500403

- Fax: +86-316-5276997

- Email: sales@gnseparation.com

- Location: Beijing,China

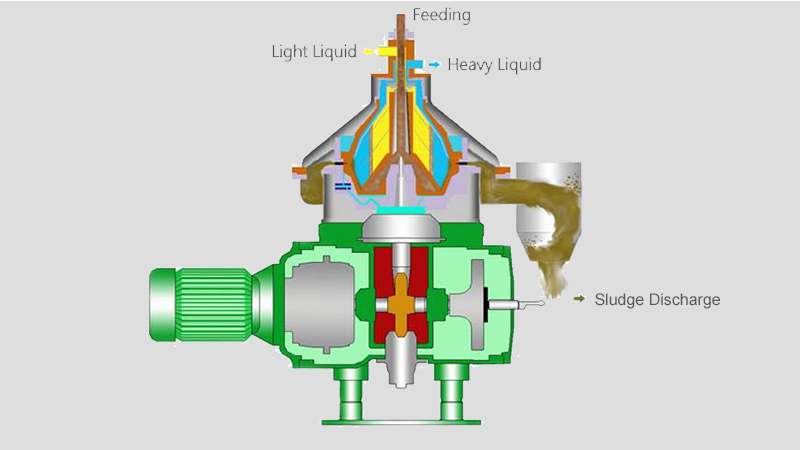

GN 3 phase disc stack separator is a high-speed, stable, sealed, efficient, and automatic slag discharge 3 phase separation equipment. It is widely used for liquid, liquid, solid 3-phase separation or liquid-liquid separation. The 2-phase solid-liquid separation disc separator has only one liquid discharge port and one slag discharge port, while the 3-phase disc separator has two liquid discharge ports and one slag discharge port, which can separate two liquids with different specific gravity at the same time. It can also discharge solid phase materials. Compared with the 3 phase decanter centrifuge, the 3 phase disc separator has larger rotation speed and G force. The 3 phase decanter centrifuge usually has a separation factor of about 3000G, while the 3 phase disc stack separator G force is up to 12000G. Therefore, the 3 phase disc separator can more thoroughly separate liquids with different specific gravity and the liquid phase discharged is more clarified. However, compared to 3 phase decanter centrifuges, 3 phase disc separator is more used to separate materials containing fine particles, with less solids content. So before entering the 3 phase disc separator, the material can separated by the decanter centrifuge for pre-stage separation to reduce the solids content and remove big particles.

The separated material enters into the heart of the machine, that is, the inside of the bowl. Under the action of strong centrifugal force, the material passes through a set of disc bundle separation intervals. With the neutral holes of the disc as the interface, the liquid with larger specific gravity moves along the disc wall towards the outside the neutral hole, where heavy slag accumulates in the sediment area, and the heavy phase liquid flows upward to the centripetal pump; the lighter liquid with a smaller specific gravity moves along the disc wall into the neutral hole and converges to the lower centrifugal pump. The light and heavy liquid phases are discharged by the lower centrifugal pump and the upper centripetal pump respectively; the heavy slag is regularly discharged; continuous production is implemented.

| Model | GNSD-40 | GNSD-90 | GNSD-125 | GNSD-225 |

|---|---|---|---|---|

| Type | Liquid-Liquid Separation (or Liquid-Liquid-Solid) | |||

| Bowl Dia | 440mm | 580mm | 620mm | 800mm |

| Sliding Piston | 380mm | 500mm | 550mm | 700mm |

| Theoretical Capacity | 1-2 m3/h | 5-10m3/h | 10-15 m3/h | 20-25m3/h |

| Max Speed | 7100RPM | 6150RPM | 6000RPM | 4500RPM |

| Max G Force | 12409G | 12273G | 12488G | 9063G |

| Motor Power | 11KW | 18.5KW | 30KW | 45KW |

| Feeding Pressure | 0-0.1Mpa | |||

| Starting Time | 10-15Minutes | |||

| Feeding Material | Solids content less 3% | |||

| The above specification and parameters for reference only. | ||||

All parts contacting with the material are made of high-grade stainless steel, which effectively reduces the chemical interaction between the separated material and the surface of the contacting part. The separated light and heavy phase liquid materials are output by two centripetal pumps of different sizes. This machine adopts upper feeding, which has lower inlet pressure on the material. Hydrodynamic coupling and a pair of helical gears or belt drive are used in the power transmission. The speed increase is stable and overload protection can be performed.

The slag discharge action of the sliding piston is automatically controlled by a PLC fully automatic control cabinet specially designed with safety protection devices. It is high level automation, strong adaptability for process adjustment, and convenient adjustment, low noise and good separation effect. Professionally designed centripetal pump system is with stable output pressure, large adjustment range and easy operation.